Vibratory Grinding

Perfect Surface Finish for your Products.

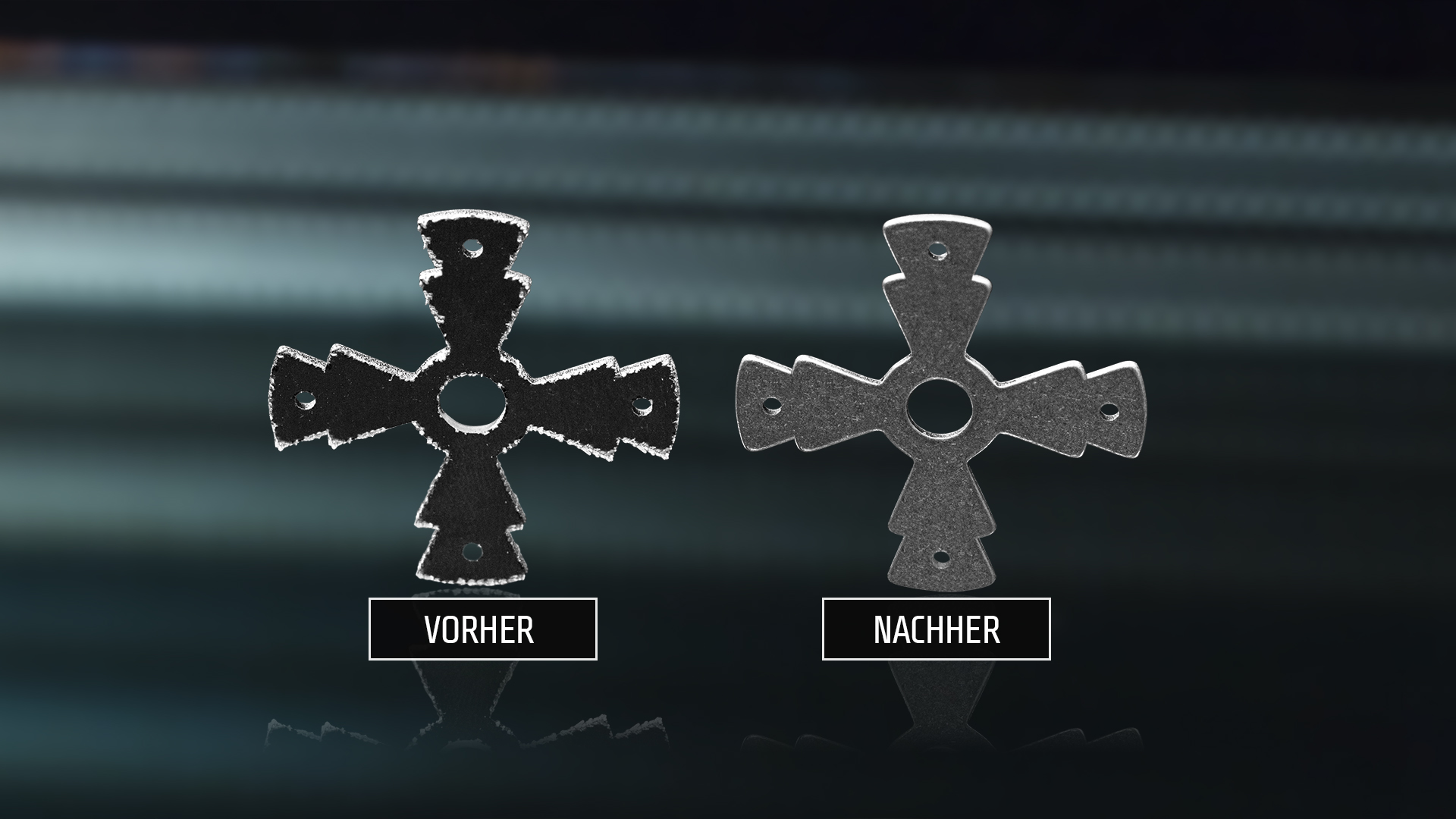

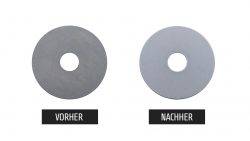

The highly effective vibratory grinding, based on the disc centrifugal force method, has turned out to be an ideal process for rigorous surface finishing, perfectly suited for smallest parts. Our machine features a specially developed and patented zero gap system enabling punched, turned or milled parts up from Ø 0.5mm and sheet thicknesses up from 0.08mm to be deburred, ground or finished.

The intense process is based on different centrifugal forces acting between workpieces and grinding respectively polishing tools. Its efficiency exceeds the results e.g. of conventional vibrators by factor 20. This fact ensures process reliability of edge ablation as well as a very uniform surface, with defined roughness values being ensured.

Due to the quality of our work, combined with quick and flexible response times, vibratory grinding has gained considerable reputation among the clientele.

You are welcome anytime to test the potential of our efficient disc centrifugal force method by sample treatment, free of charge and without any obligation.

Our technicians are at your disposal for consultation and elaboration of a special treatment procedure tailored to your application.

Vibratory Grinding by

Disc Centrifugal Force Method

Benefits

- Fast and absolutely reliable, high process safety

- No undesirable deformation of workpieces

- No loss of parts thanks to zero gap system

- Economical method also for treatment of very small parts

- Large scope from deburring up to high gloss polishing

- Process speed increased up to factor 20

Specific Know-How and

Selection of Consumables

Set-up of Parameters for a Perfect Surface.

The quality of the resulting surface is determined by the correct selection of consumables and an optimum process program. Each workpiece must be assessed individually. Our specialists have many years of experience and well-founded know-how in adapting carefully composition and shape of consumables as well as process parameters for every single case.

Meeting these challenges is our daily motivation. After thorough consultation and evaluation, we determine process parameters and consumables for perfect surface treatment of your workpieces. We do not stop before customers are satisfied.

Grinding, Deburring, Polishing

Gapless Surface Finishing in Every Corner.

Our machine, based on the disc centrifugal force method, has been developed for vibratory grinding and polishing of smallest parts (up from Ø 0,5mm). The zero-gap system provided is also able to process very filigree and thin workpieces or sheet thicknesses up from 0.08mm.

Whether aluminum, steel, stainless steel or non-ferrous metal – from deburring and grinding or smoothing up to high gloss polished surfaces – we apply the right surface finish to your workpieces.

Our service for you:

You are welcome anytime to test the potential of our efficient disc centrifugal force method by sample treatment, free of charge and without any obligation.

Our technicians are at your disposal for consultation and elaboration of a special treatment procedure tailored to your application.