Non-contact cleaning. Quick, intense and still gentle to material.

Without any effort, rust, lacquer, oil, soot coatings, oxides and many other contaminations can be removed from metal, wood, natural stone and concrete. Our mobile laser cleaning systems clean every surface in a non-contact procedure without leaving residues.

The base material itself is not damaged, and -thanks to fine-tuning of parameters- even the state of high gloss polished surfaces remains unaffected. The laser beam cleans the surface without leaving a trace. Rust and oxide resistance of stainless steel and aluminum remain intact.

Pulse power, scanning rate and cleaning pattern can be fine-tuned, so that the material quantity removed by a single laser pulse can be controlled at maximum precision.

The absence of chemical solvents or other consumables contributes to high environmental friendliness as well.

The laser can be operated by hand gun, so that all positions of difficult access can be reached. Fine-tuning of laser parameters is done in no time, by means of the tablet included in the delivery.

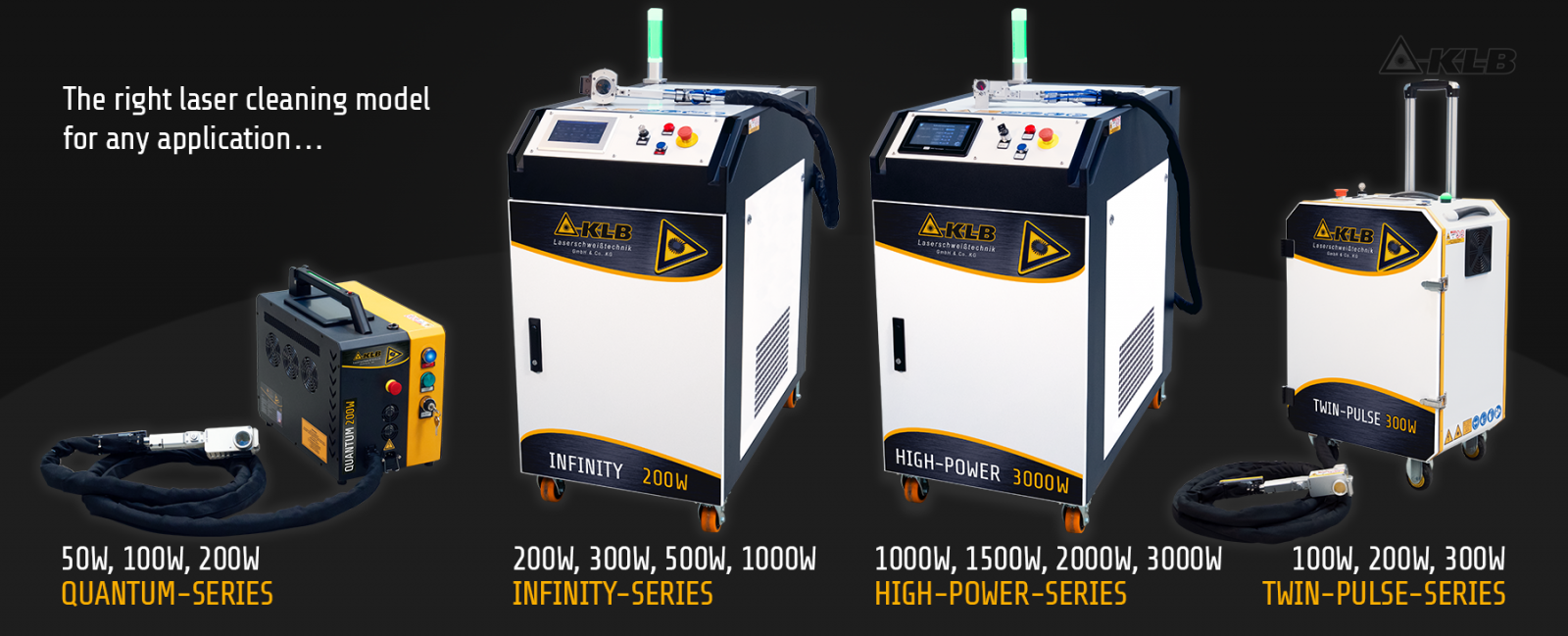

The correct cleaning power for every application:

The laser cleaner 100 W proves to be the right choice for sensitive surfaces and delicate tool molds. This compact and portable model can be carried around and used inside cases, containers and pipes.

Cleaning of large areas and intensely contaminated components are the specialty of the 1500W laser cleaner. The enormous power eliminates dirt even from oily and rusty threads and textures in a flash

Possible applications:

- High-End cleaning of plastic injection molds

- High-End cleaning of tool molds

- High-End cleaning of surfaces

- Cleaning of weld seams

- High-End cleaning of motors and accessories

- Cleaning of surfaces consisting of concrete or natural stone

Benefits:

- Simple to learn and to practice.

- Dry and clean

- Low noise level

- In contrast to blast clean, no edge rounding produced

- Base material is neither removed nor damaged

- Surface remains free of scratches, thanks to non-contact technology

- Also for polished and very sensitive surfaces

- Surface structure and high gloss properties remain unchanged

- For small and large areas

- Zones hard to reach do not represent an obstacle

- Thoroughness and efficiency exceed the results of many other cleaning methods

- Accurate and controllable beam

- Residues nearly absent

- Quick procedure and minimum delay

- Integration in production and assembly lines possible

- Minimum maintenance

- Low operating cost

Your own laser cleaning system...

...exactly adapted to your particular needs.

Should you be interested in an own laser cleaning system, do not hesitate and consult our factory service. Customized solutions can be configured anytime. We inform you also about prices and delivery times. In between, we will be pleased to offer you a rental machine, so your project can be launched at once.

Purchasing one of our cutting-edge laser cleaning systems provides a stable basis for long-term order processing on site at lowest cost. We deliver only machines which we have thoroughly tested and used in our own production, knowing each model in detail. For this reason, we can offer service and support for the entire life cycle.

Choose the machine best fitting your applications. In order to assist your decision process, we invite you to a demonstration date anytime.

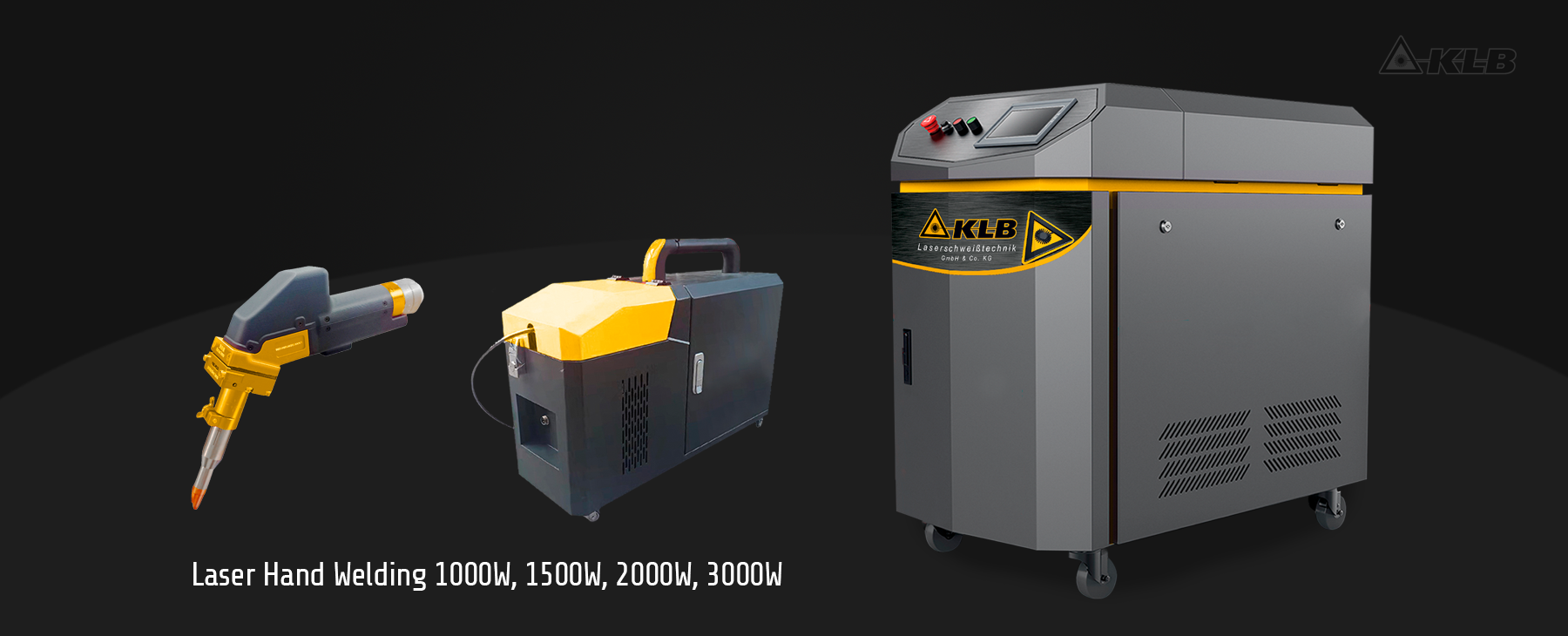

Mobile Laser Hand Welding Units

Increased speed, maximum user friendliness and a wide scope of applications belong to the major benefits of laser hand welding method, which is currently revolutionizing the industrial market. Compared to well-known TIG welding, it exceeds the speed by factor 4. Users become quickly familiar with the method and are able to deliver good results within short time. Positioning of the laser gun does not give rise to difficulties, even in locations to reach. This extends the scope to highly complex assemblies.

Besides practical points of view, the excellent quality of the resulting seam proves to be an advantage of this method. Warping is considerably reduced -compared to seams produced by TIG welding-, and the optical appearance of fillet welds is enhanced without any negative impact on mechanical properties.

Lower warping thanks to targeted heat input -

Maximum productivity and flexibility.

Only one quarter of the working time usual in a TIG – welding procedure is needed for comparable laser welding. Simply position the lightweight laser gun (0.5 kg) at the required place, no matter if it is difficult to reach. Welding nozzles are selected according to the requirement: Fillet or butt welds, corner welds or outside seams. The concentrated energy input enables homogenous root seams to be produced.

Costs for preparation and rework, e.g. for grinding and polishing, are often no more necessary – this represents an economical advantage over conventional methods. Furthermore, as the method manages without large heat input, reduced warping contributes to elimination of straightening work normally required.

For various materials and a wide thickness range, laser welding delivers valuable and reproducible results with excellent mechanical properties. Personnel can conveniently be trained without major effort. Even welders with many years of experience are surprised by the results.

Our factory service is looking forward to presenting you the equipment in a live demonstration anytime.

Innovative Highlight:

The Double Wobble Welding Head

Dieser speziell entwickelte Wobblekopf vergrößert die Schweißbreite zusätzlich um bis zu 5mm. Dadurch können größere Spaltmaße ideal überbrückt werden. Die Frequenz und Breite des Wobbleschweißens kann individuell auf die entsprechenden Anforderungen eingestellt werden. Hierdurch ergibt sich eine Vielzahl an neuen Bearbeitungsmöglichkeiten, so dass trotz gewisser Spaltmaße optisch ansprechende und haltbare Schweißnähte hergestellt werden.

Specification:

| Laser power Laser wave length Penetration depth Laser source type Humidity Ambient temperature Power supply Cooling method Power consumption Length of fiber optic cable Laser spot diameter Laser head Safety button Alarm lamp Weight Hand Gun Machine dimensions (WxHxD) Gross weight machine |

1000W / 1500W / 2000W 1064nm <5 mm (depending on laser power and material) Fiber laser <70% <40°C 230V / 230V / 380V (32A) Water cooling 5500W / 6500W / 8800W 10m, up to 15mm as an option 0-5mm Patented Mini-Wobble-head yes yes 0.5KG 632 x 1240 x 1204mm 238KG (incl. cooling water) |

Application in different sectors:

- Tank construction and equipment engineering.

- Mechanical engineering.

- Plant engineering.

- Metal and sheet metal processing.

- Pipe production and processing.

Benefits:

- Process speed exceeds TIG welding by factor 4.

- Simple to learn and to practice.

- Narrow and durable welding seams, good optical appearance.

- Homogenous root seams are possible.

- Suitable also in positions difficult to access.

- Low heat input into material surface.

- For this reason: Considerable reduced warping

- Neither spatters nor undercut.

- Treatment possible in precisely defined places.

- Appropriate for both thick plates and thin metal sheets.

- Low rework cost.

- Minimum maintenance.

- Low operating cost.

Features:

- Adequate laser power for every application: 1000W, 1500W or 2000W.

- Models with single or double wobble welding head available.

- Flexible adjustment of laser spot diameter between 0 and 5mm.

- Precision software for wire feed under automatic control.

- Double wobble welding head with 6 welding patterns.

- Simple use: Welding parameters pre-configured, focal length simple to adjust.

- Lifetime of rotating deflection mirrors increased by factor 6.

- Fiber laser with water cooling for permanent use.

- Lightweight handgun for welding: Only 0.5KG.

- Length of flexible fiber optic cable: 10 m, up to 15 m as an option.

- Lifetime of the machine: 10 years min.

- High efficiency, low space requirement, high flexibility.

- No UV radiation and ozone formation by laser welding.

- Outstanding price / performance ratio.

- Menu language selectable.

- Warranty: 2 years for laser source, 1 year for other components.