Repair Welding of

Tool Breaks

100% - as good as new!

Tool breaks often arise as a consequence of excessive operational load, not to be excluded in the presence of two boards inside the tool mold. The double material thickness of the boards during pressing procedure entails increased pressure, able to blow apart the mold into two or more partial segments.

The first repair step for cracked tools or broken off partial segments consists in grinding off or gouging the entire break cross section, to eliminate all flaws. Then the tool is preheated in a chamber furnace, the cross section filled up by weld buildup layer by layer by means of a special alloy, so the original state of stability is reestablished.

In order to ensure a long lifetime, we take off the entire cross section of the break, which will be filled up again afterwards, layer by layer. Our method, in-house developed, is characterized by the fact that it causes merely a minimum of warp.

Benefits

- Only short interruption of production

- For this reason, deliveries do not need to be cancelled

- Contractual penalties are avoided

- Cost savings also from a technical point of view

Our knowhow saves hard cash:

Applying filler beads to a tool mold normally gives rise to high deformation stress. Thanks to our specially adapted method, this warping can be reduced extremely, and repair takes place respecting even narrow tolerances. For this reason, your tool within no time will be available again for the next operation.

A small selection of tool breaks, successfully repaired by our specialists:

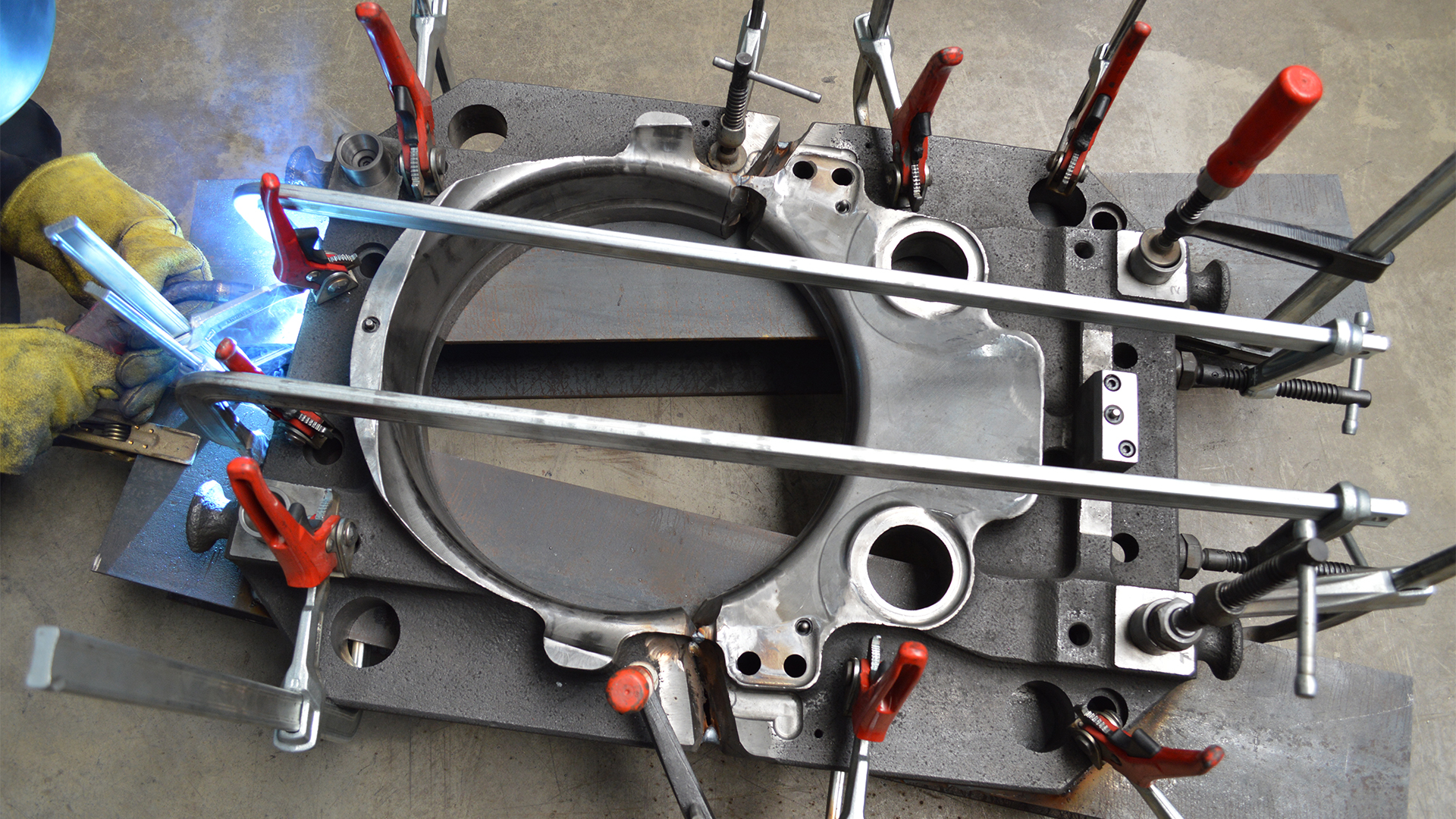

Repair of a tool break by MAG welding

Each tool break must be individually assessed, to find the optimum method for repair. The tool illustrated above consisted of CR7V, and the mold was split up into two partial segments. The challenge consisted in complete filling up of the entire cross section, simultaneously keeping clear the cooling bores, in order not to impair their functionality. This way, durability of the mold could be reestablished in a qualified manner. Wear resistant hard-facing of the surface in these cases is possible as well. For more details concerning MAG welding, refer to the following section here.

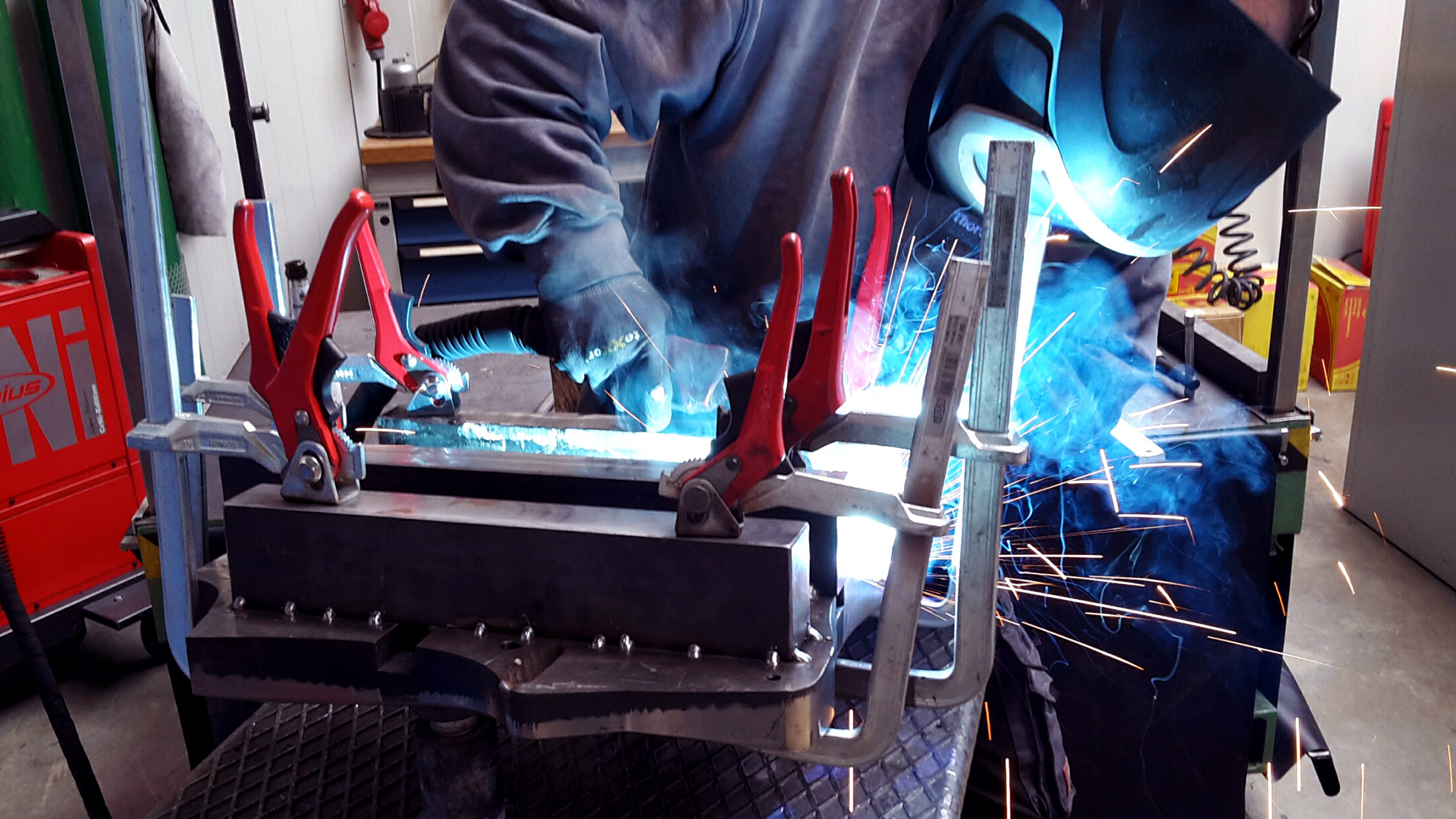

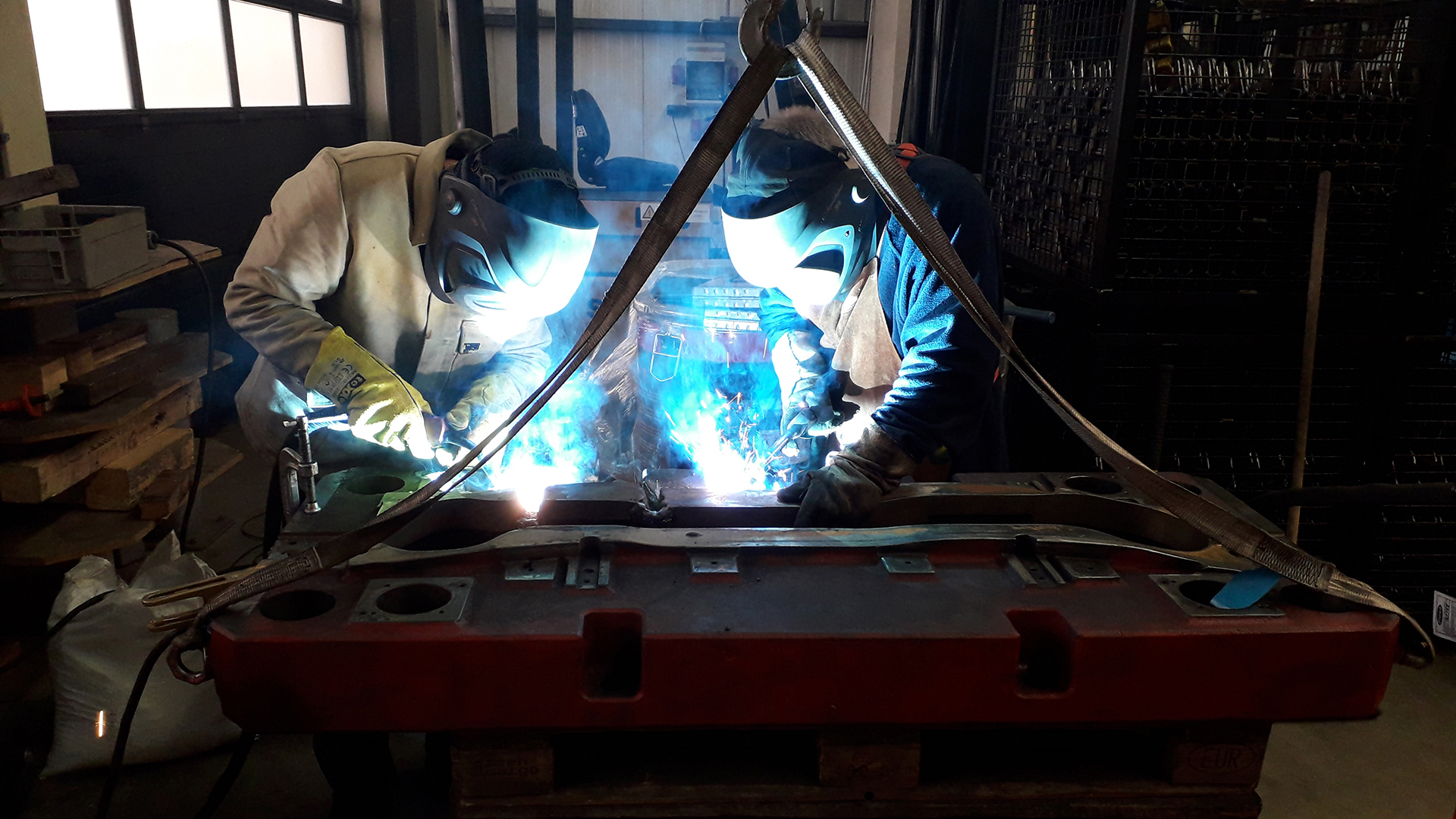

Repair of a tool break by TIG welding

Depending on kind and severity of the damage, we select -in coordination with the client- the adequate joining method. As shown above, TIG welding offers the possibility to restore the shape of the broken off partial segments, layer by layer, in a durable manner.

This method enables modeling to be performed without any problem, so cooling bores remain clear with unaffected functionality. Upon request, arising material ingress can be removed afterwards by laser welding. For more details concerning TIG welding, refer to the following section here.

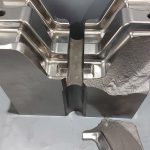

Repair of a tool break by LASER welding

Laser welding is known as a method introducing the least quantity of stress and is distinguished by the fact, that material can be applied in a delicate and pinpoint manner. For these two breaks we have opted for laser welding, because the damaged and broken off contour was relatively thin. Laser welding did not give rise to major stress, therefore the formation of new cracks in the base material could be avoided.

This low-stress joining method represents a qualified and quick method of component repair, and the tools will be available again to the production within shortest delay. For more details concerning laser welding, refer to the following section here.