Automated

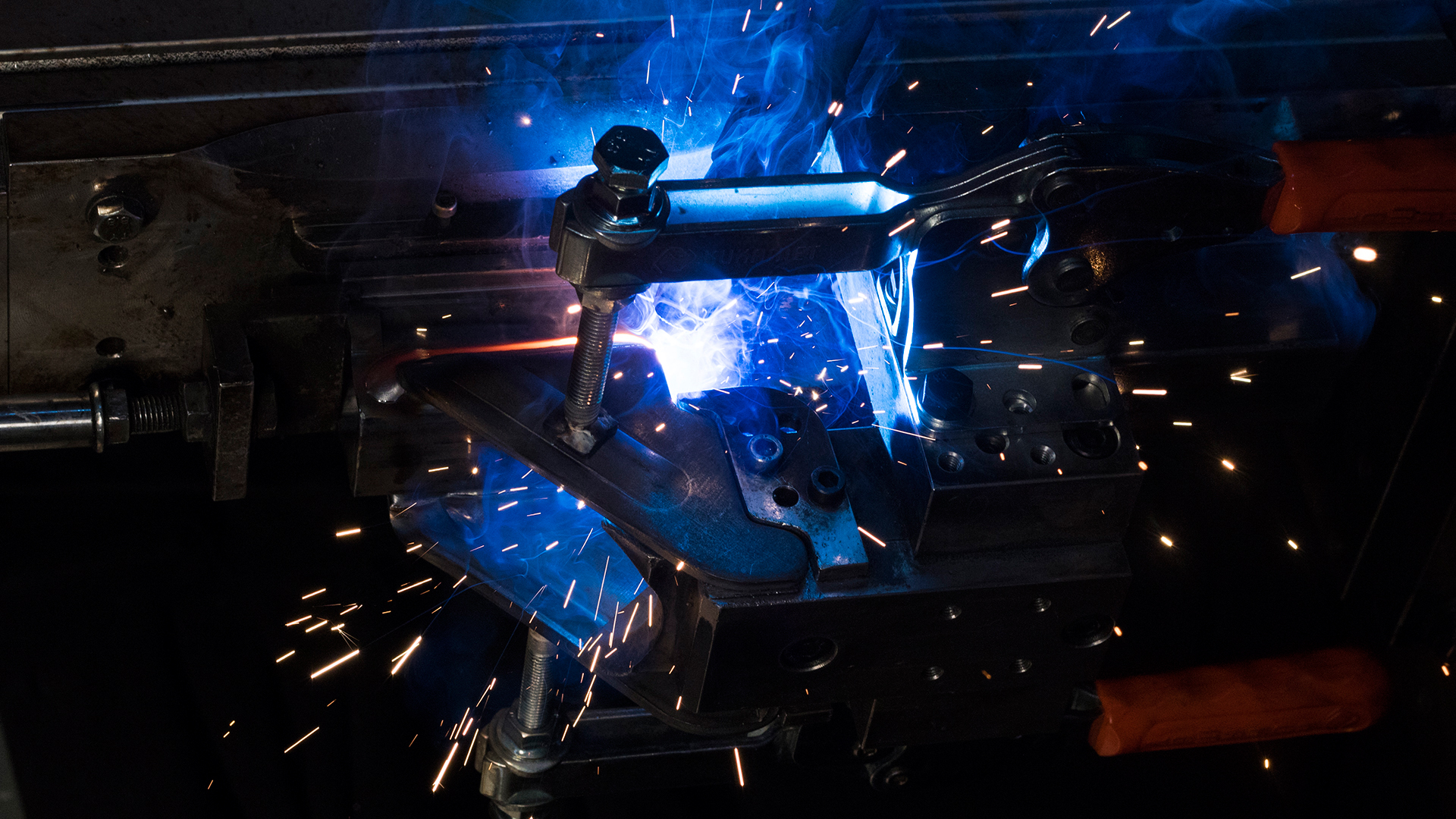

Robot Welding

Man vs. Machine

Due to safe use and low-cost processing capabilities, robot welding meanwhile is a widespread joining method in industries. In spite of classical manual welding operations frequently still being in practical use, the advantages of programmable systems cannot be ignored.

Short process cycles and high throughput times are attainable already for small series production, without negative impact on quality. As parameters can be optimized without major effort, warping is often reduced, so that rework can be minimized.

As our demands on ourselves exceeds usual standards, we have obtained the following certification:

DIN EN ISO 9001:2018

Welded assemblies of up to 1800mm length can be manufactured by our robot plants. The compact cells are perfectly suited for automated prototype and serial production, meeting all requirements regarding safety and control possibilities.

Benefits

- High and reproducible welding quality

- High process speed ensures short order times

- Thanks to precise parameter selection, welded seams dispose also of optically favorable properties

- Optimized process sequence lowers warping

- Outstanding accuracy

- Reduction of rework

When may we start serving you?

Derive benefit from our MIG/MAG welding capabilities for prototypes and serial production.

Our smartCell

Our new smartCell® model significantly accelerates programming of assemblies. We have opted for this type of robot cell not without reason, as we are able this way to lower set-up and programming cost for the clientele. Even for small series <100 items, cost-effective manufacturing is possible.

On the basis of MAG welding by means of CMT, your components can be assembled nearly without spatters, and welding seams are generated, which provide an attractive optical appearance.