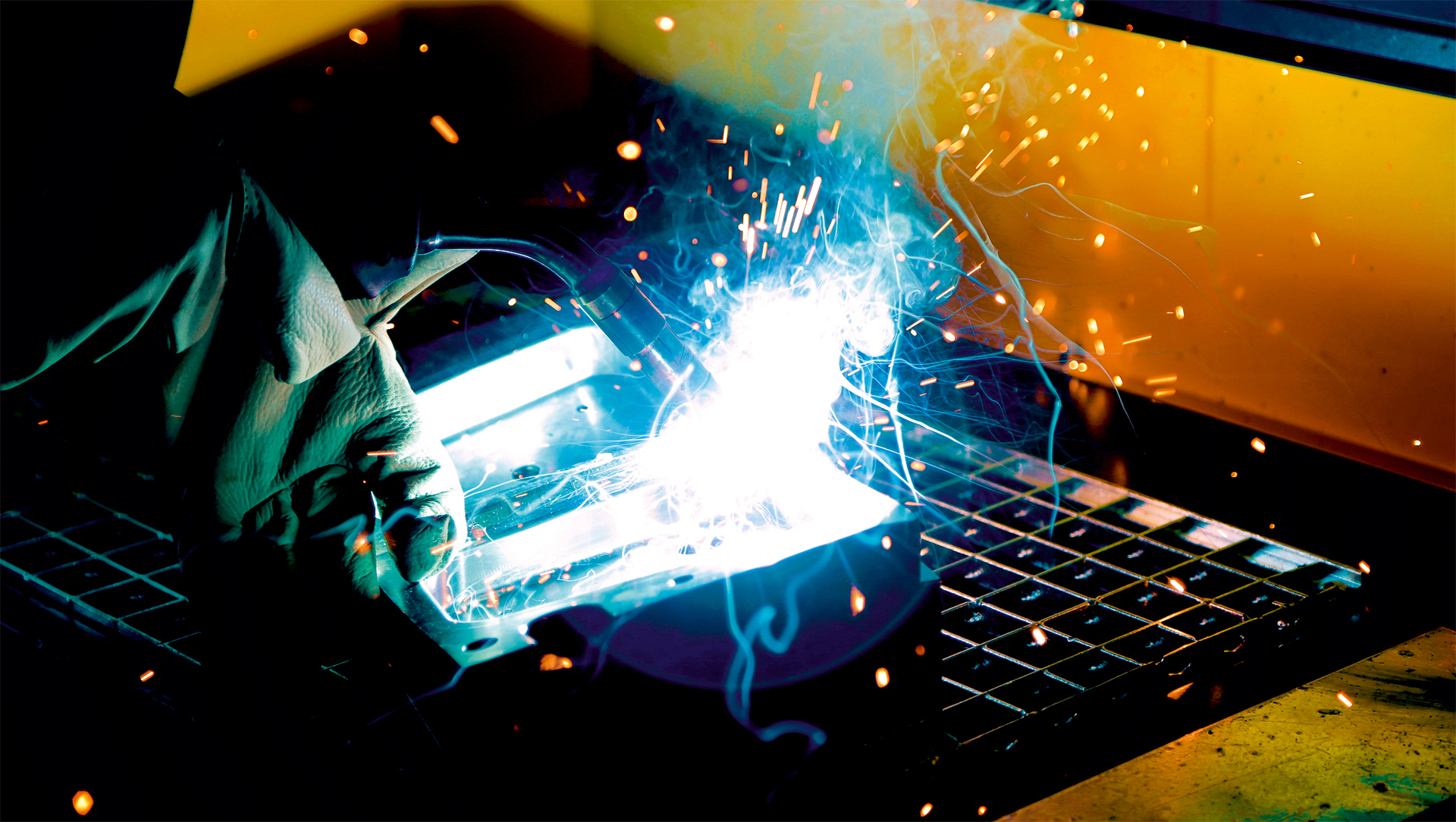

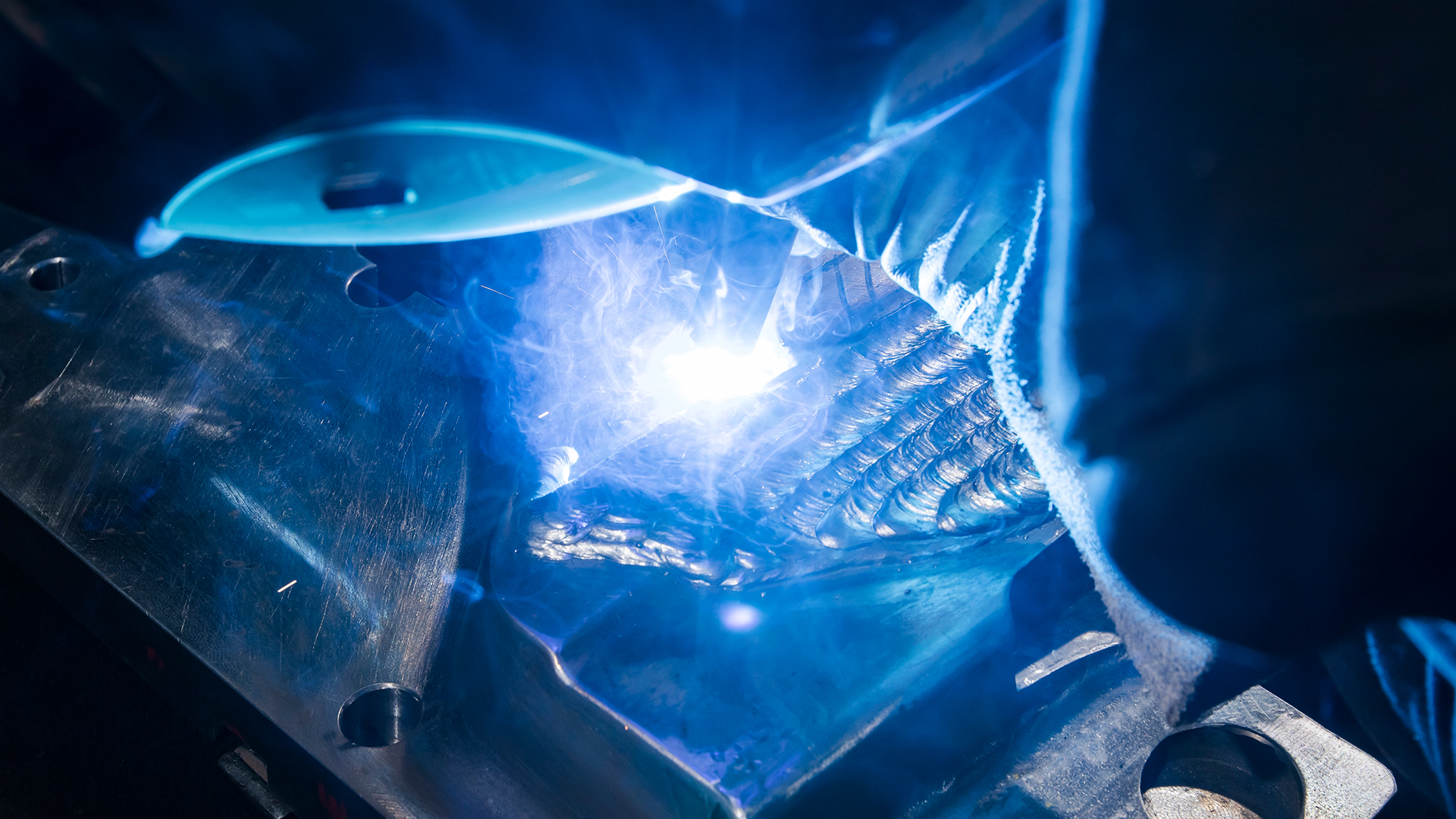

MAG-Welding

Tool and Mold Making

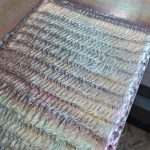

A high deposition rate is the particular advantage of this well-known method, so it proves to be the optimum choice for deposition welding on large surfaces, for repair welding in the case of tool break or for flood welding of dies. Our portfolio includes deposition welding of nickel-base alloys of molds as well.

For each layer, the quantity of applied material may amount to up to 3 mm. The process can be the carried out as soft, medium or hard application, in one single or several layers. In these situations, MAG welding represents a really economical solution.

Particularly in the sector of mechanical engineering, we are regularly charged with special projects, among others multilayer deposition welding of a special brass alloy (A320) on current collector rolls, weld buildup (1.4571) on roll diameters to reestablish the nominal value, or Stellite 12 hard facing for screw tips.

Benefits

High deposition rate contributes to profitability.

- Efficiency ensured

- Quick build-up welding on large areas

- Time and cost saving method

- Weld thickness ca. 3mm per layer

- Possible also in positions of difficult access

We are specialized in:

- Hard and soft applications

- Nickel-base alloys

- Brass alloys

- High- and low-alloy materials

- Titanium alloys

- Massive and cored filler wires

- Special alloys of any kind

6 Chamber Furnaces

The right furnace for your application.

6 chamber furnaces with different volumes (chambers between 50l bis 1000l are available) are used in our factory, to preheat tools and components to the required working temperature before welding and to perform annealing after completion. For your orders, the corresponding furnace will be selected.

Maximum component size: 1650mm x 1000mm x 610mm

Metal and Sheet Metal Processing

Unlimited Assistance.

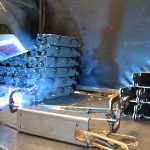

MAG welding is a decisive element of our scope of activity in this sector. For our customers, we weld single components, prototypes and series of assemblies. In less time, we are able to manufacture the desired assembly consisting of steel, stainless steel or aluminum – in optimum quality.

Whether thin or thick sheet metal, massive components, in standard or pulse welding procedure – our clientele derives benefit from our profound knowledge. For cylindrical components, our rotary axes go into action, so material is applied in a uniform manner.

Upon request, our project may include also the construction of the desired welding fixture, to maintain correct dimensions of the object to be processed.