3D– Laser Welding

by Robot

Machine and Process – the Double Solution.

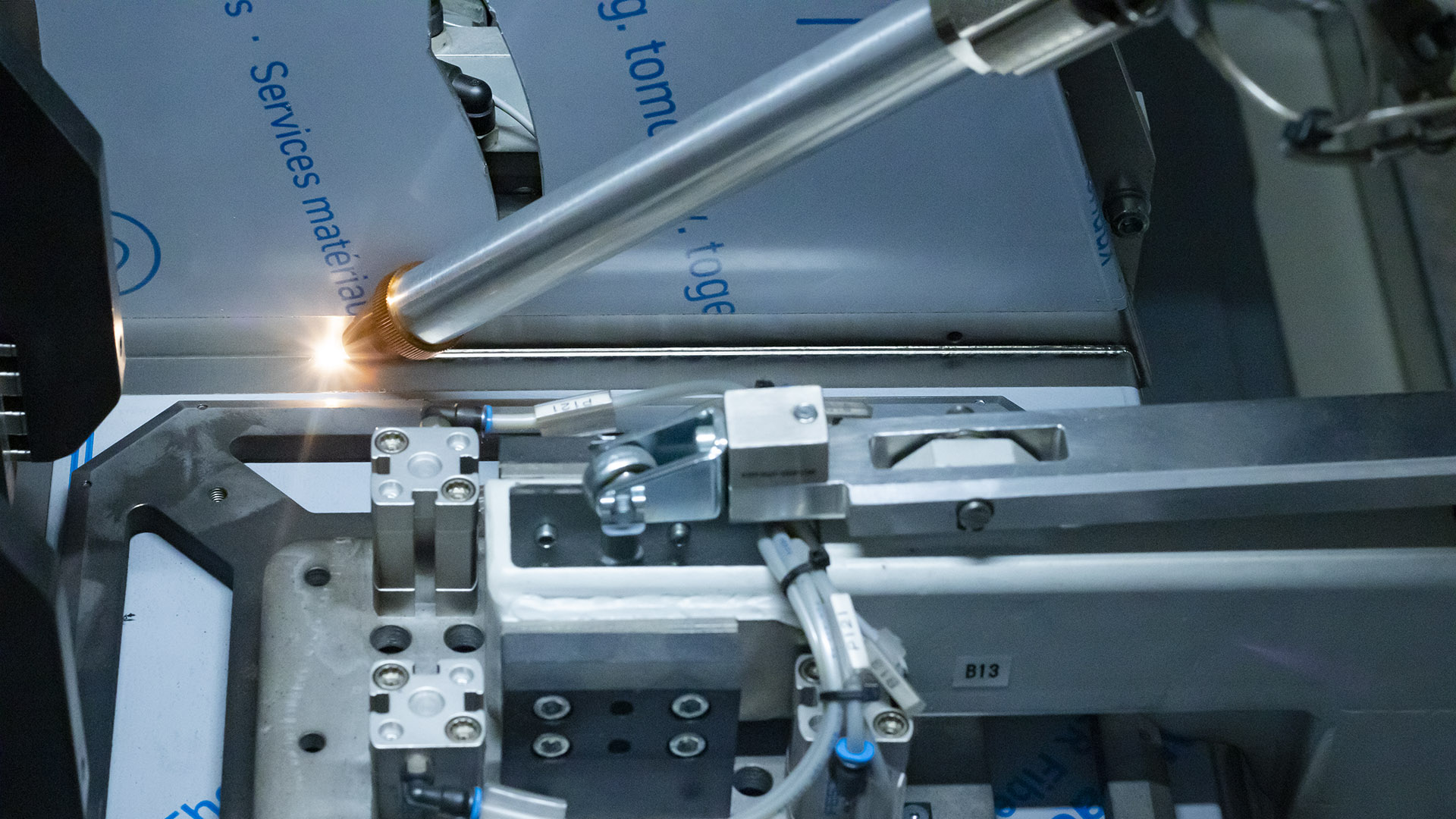

Robot – Laser welding is a safe and cost-effective method gaining nowadays more and more currency, particularly in serial production of components. Laser welding supported by a programmable robotic system achieves a new level of automation:

Short process cycles by machine-controlled routines, simultaneously offering constant quality and reproducibility, to be obtained already in small series.

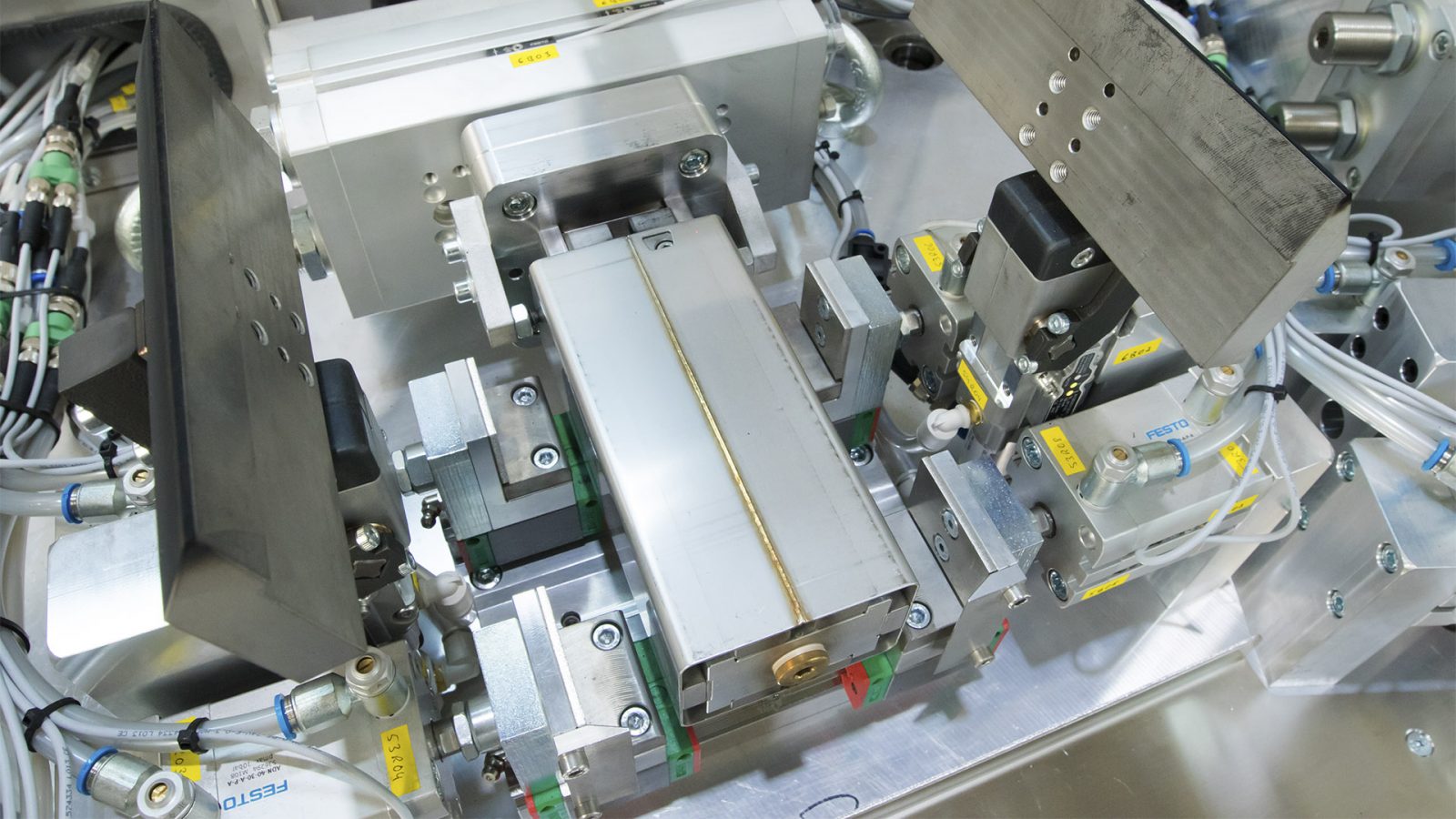

Our robot configuration has been designed with maximum flexibility in mind, in order to weld a large range of pieces of any kind. The energy required is supplied by a powerful 3KW laser. Reproducibility is furthermore ensured by fixtures constructed and manufactured together with our cooperation partners. We are always interested in developing and putting into practice the serial process of production for your components.

Adjustment of our robotic system to individual requirements is no problem: In-house design of clamping devices always gives backing to reproducibility, for laser welding and laser cutting of pieces ordered.

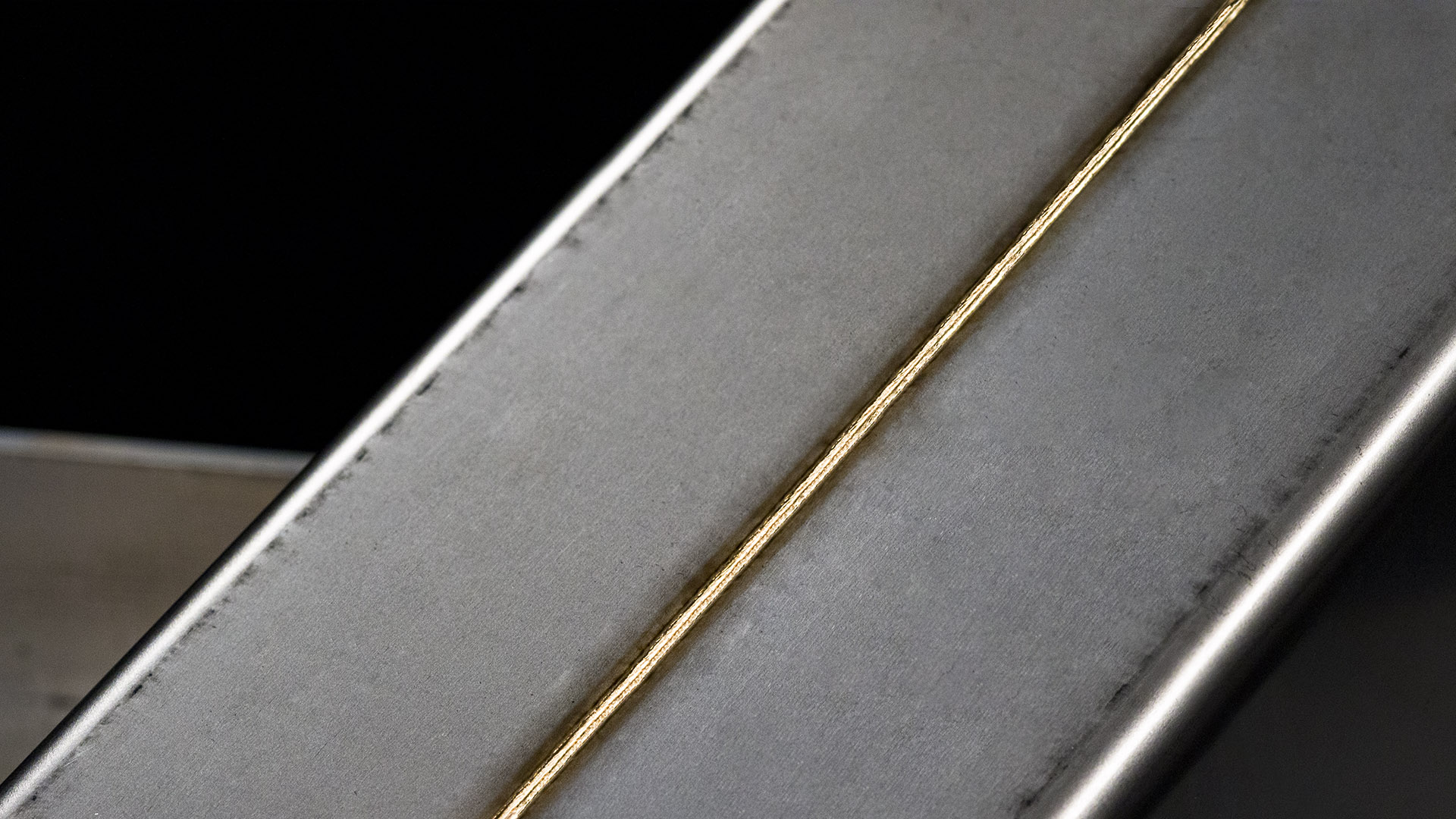

Professional fine tuning of welding parameters and optimized sequences for the seams ensure optimum quality of your components – and this result will be delivered in series.

Benefits

- Ideal method for complex objects

- Reduced warping thanks to optimized weld seam sequence

- Homogenous weld quality

- Short process cycles considerably lower unit prices

- Safe reproducibility at a high level of precision

- Rework reduced

- Microstructural changes nearly absent, due to reduced thermal input

- Optimized program routines with adequate welding parameters

Benefit from our Competence and our Service.

Our Investments in Technology of the Future:

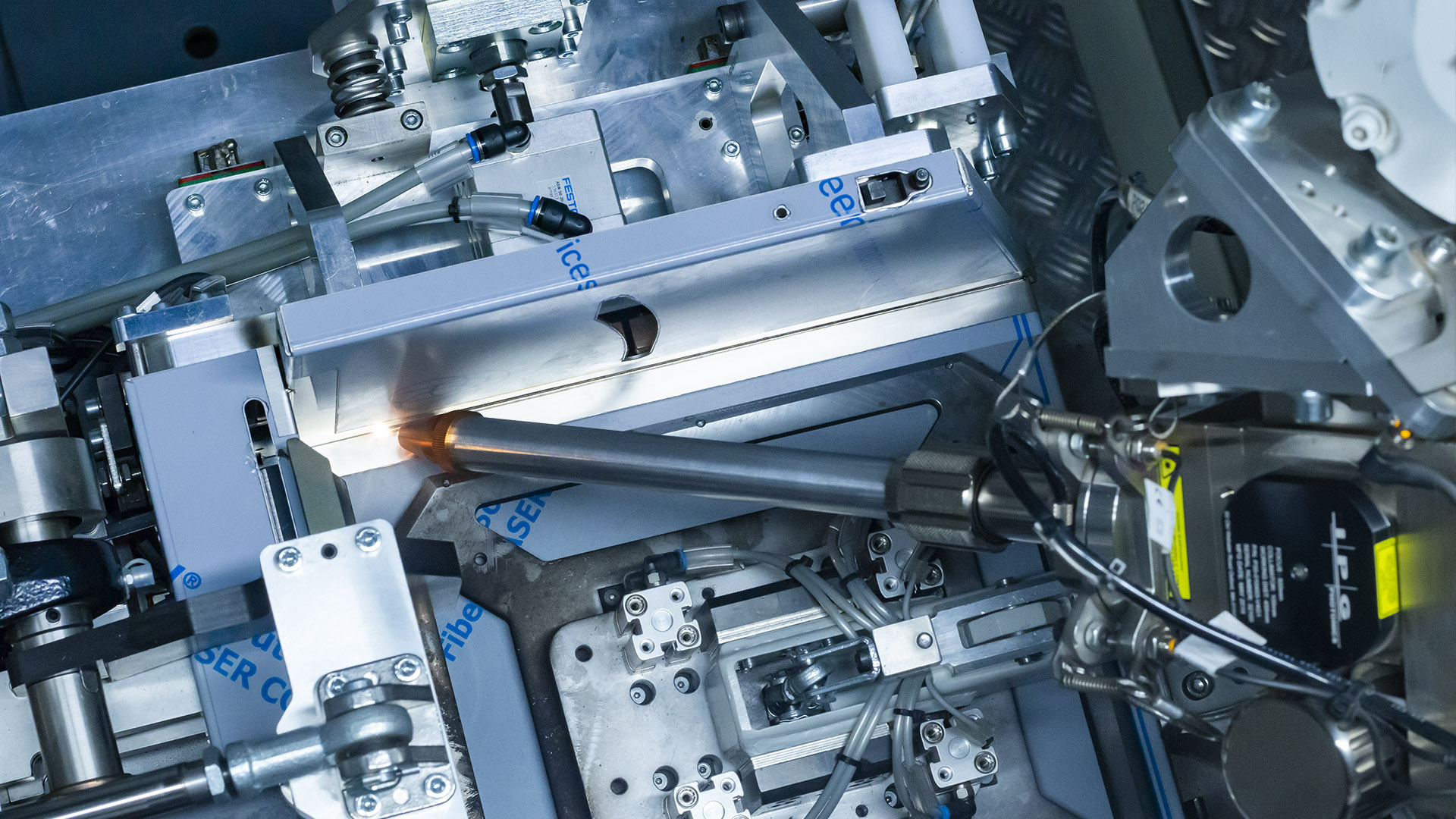

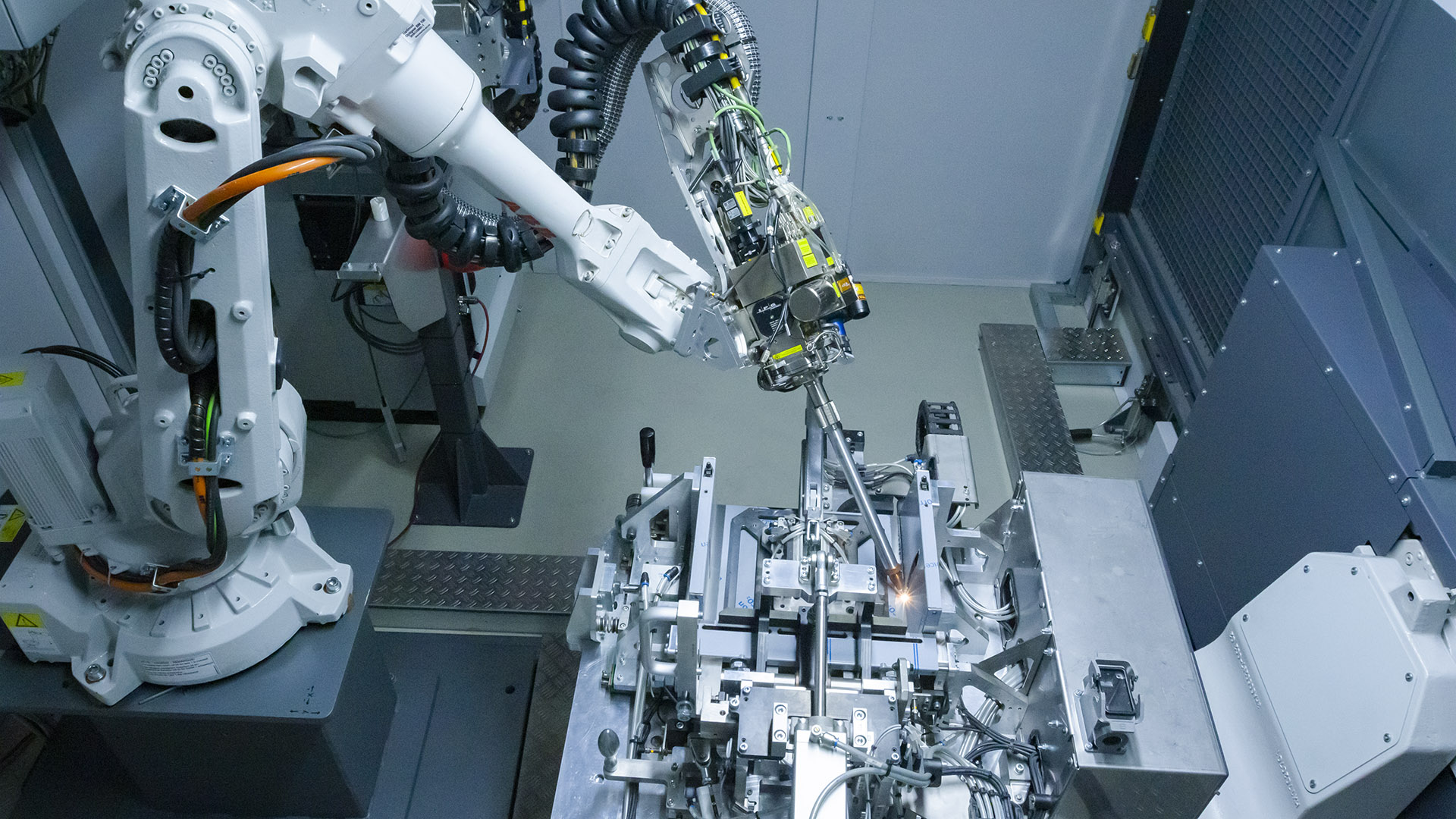

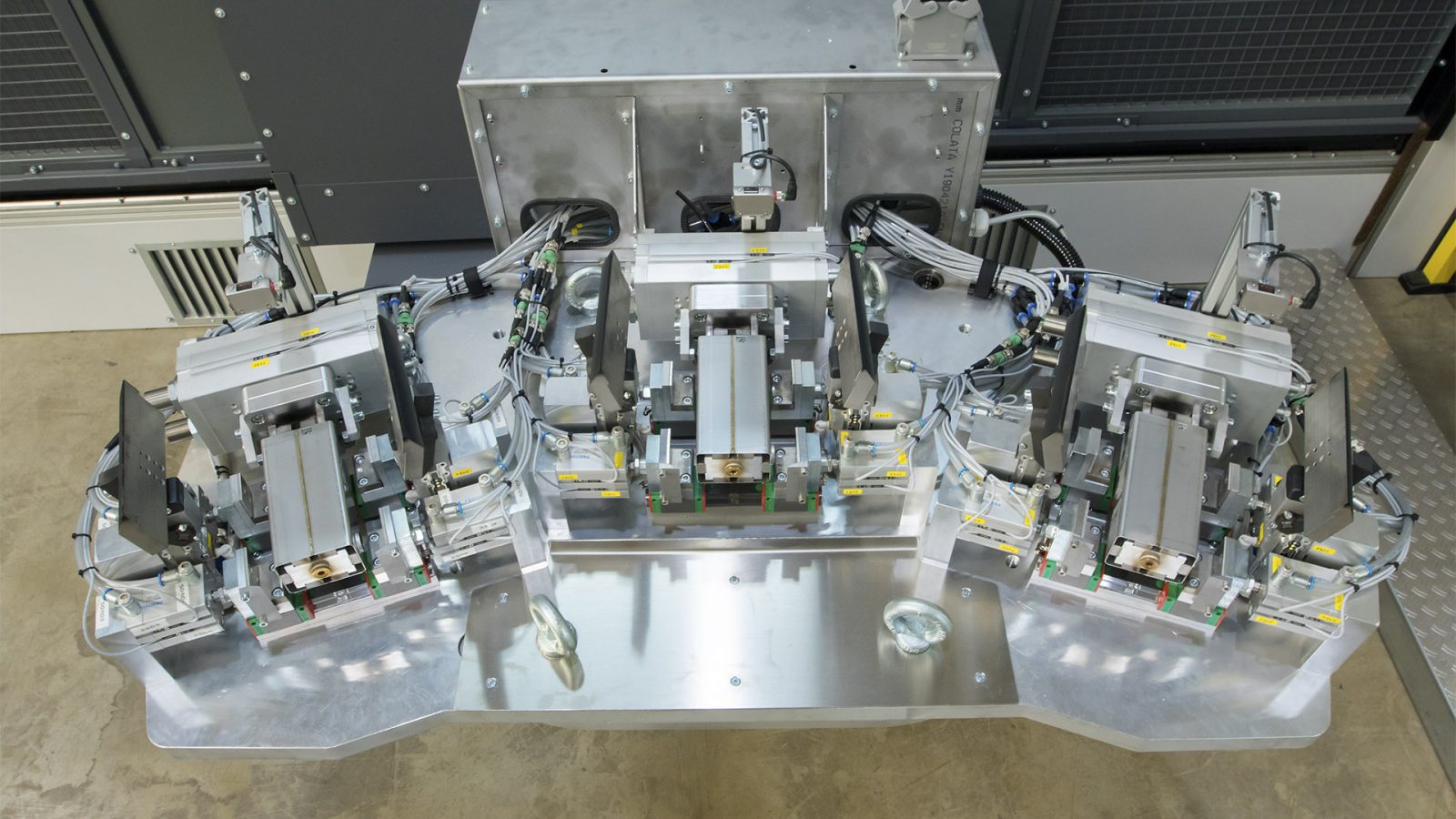

Our automated robotic system for 3D laser welding and 3D laser cutting is composed of an ABB robot and a rotary axis for positioning of components, featuring two processing stations.

As a laser source, we use a 3KW IPG laser for powerful cutting and welding of sheet metal assemblies.

The process considerably speeds up due to the fact that still during treatment of one part, the previous part at the other side can be removed and a new item inserted.

Whether welded assemblies for automotive sector, gas or electric grills, or shrouds for sanitary equipment – a large range of products can be manufactured in small or large series.

In-house development of process periphery for components of any kind:

From development up to assembly – the whole process is available from one single source. Fully automated fixtures ensure continuous reproducibility.

As exclusively high-grade (electrical and pneumatic) components are used, quality and durability of the configuration is ensured.

Depending on the size, one or several components per cycle can be welded on the station.

Together with us, your next serial production is already in the starting blocks!