Laser Engraving: Deep Engraving

Decorative Treatment of your Surfaces.

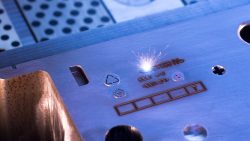

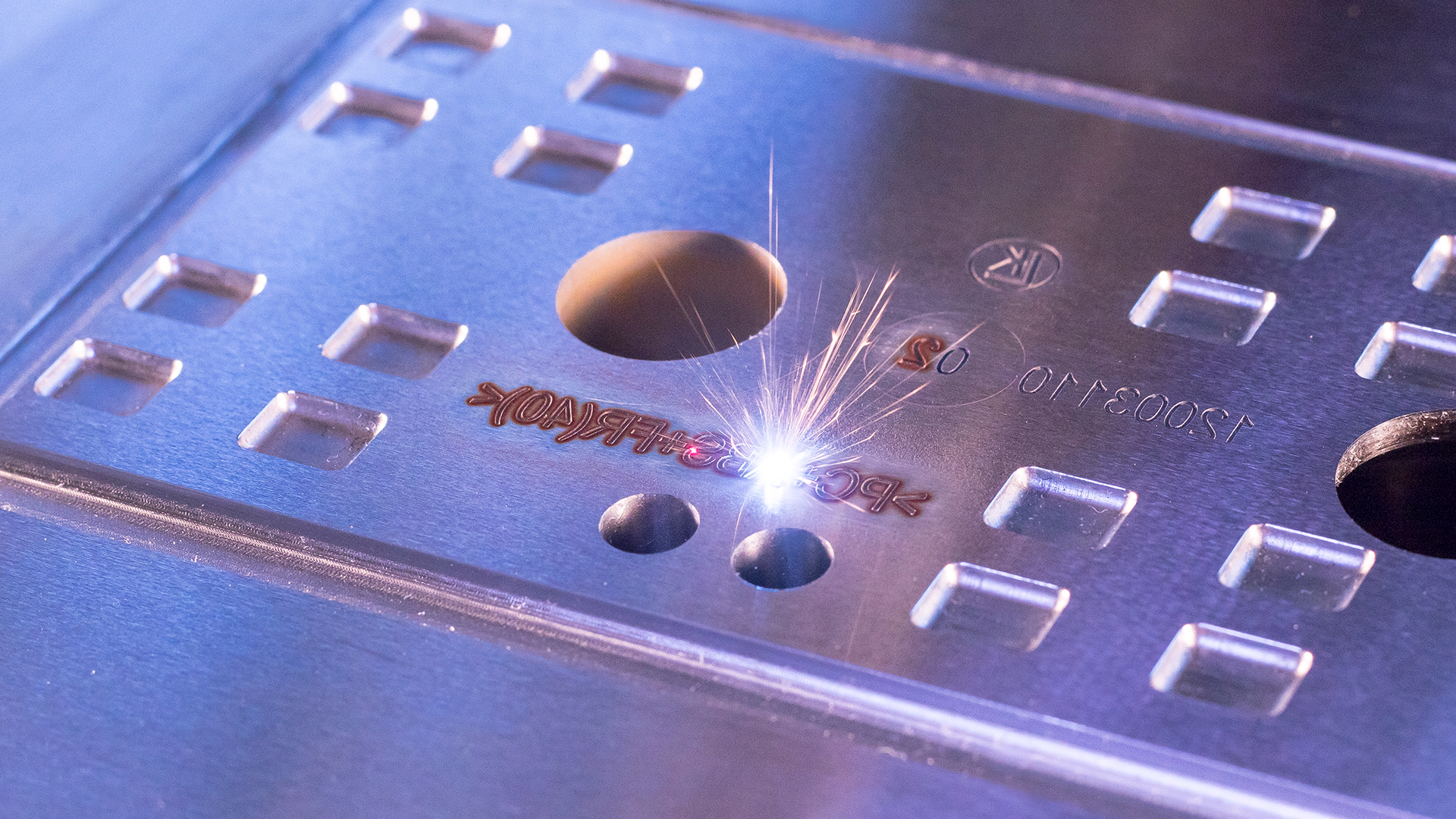

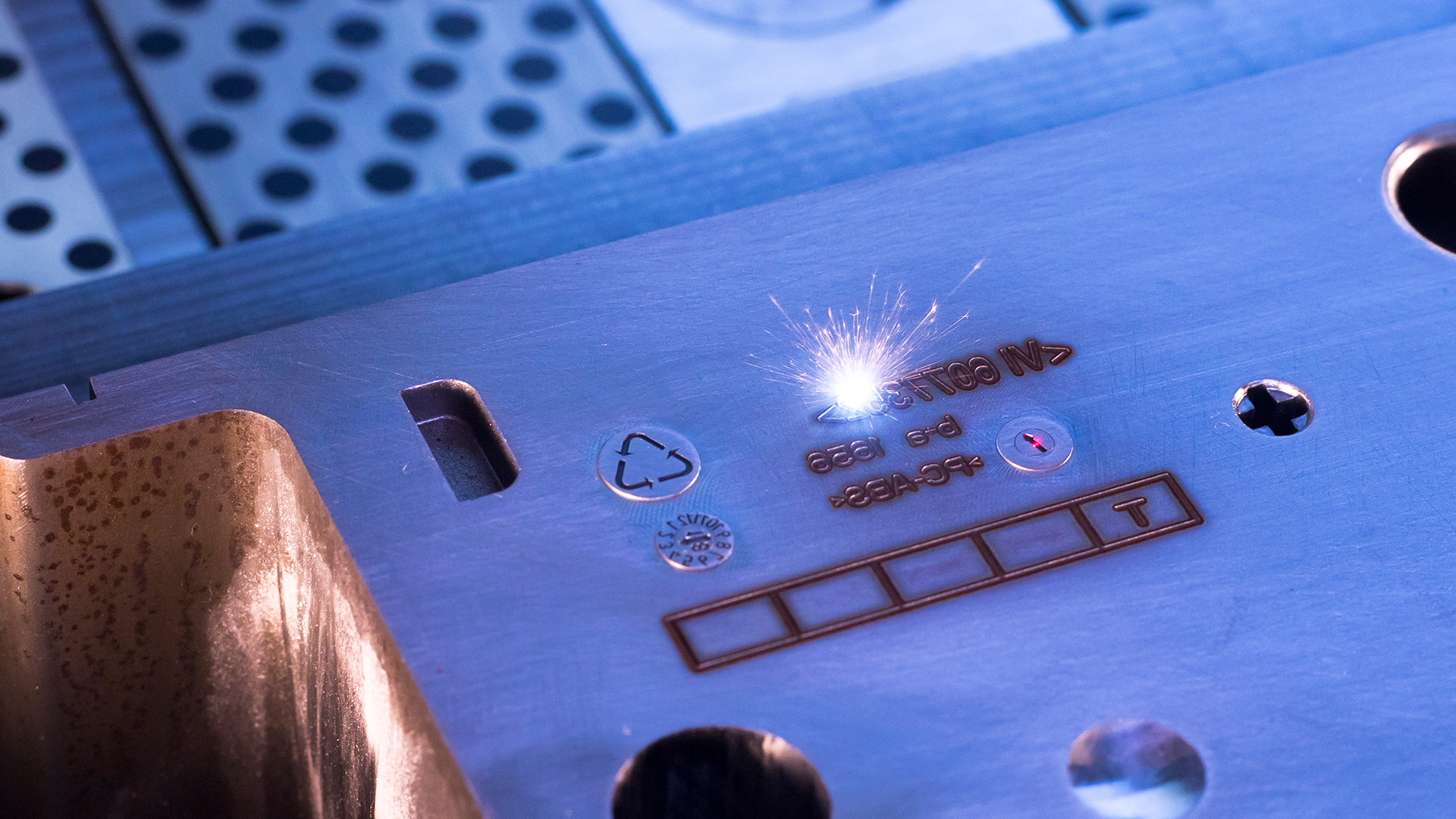

Deep engraving is a process for targeted partial removal of surfaces, thus creating a visible marking.

Deep engraving and deep labeling are technologies based on the same principle: The focused thermal energy of a laser beam is used to melt and to evaporate material. Accurate parametrization enables the depth of the engraving to be defined according to the needs of the client. Usual values are in the range between 0.02 and 0.5 mm.

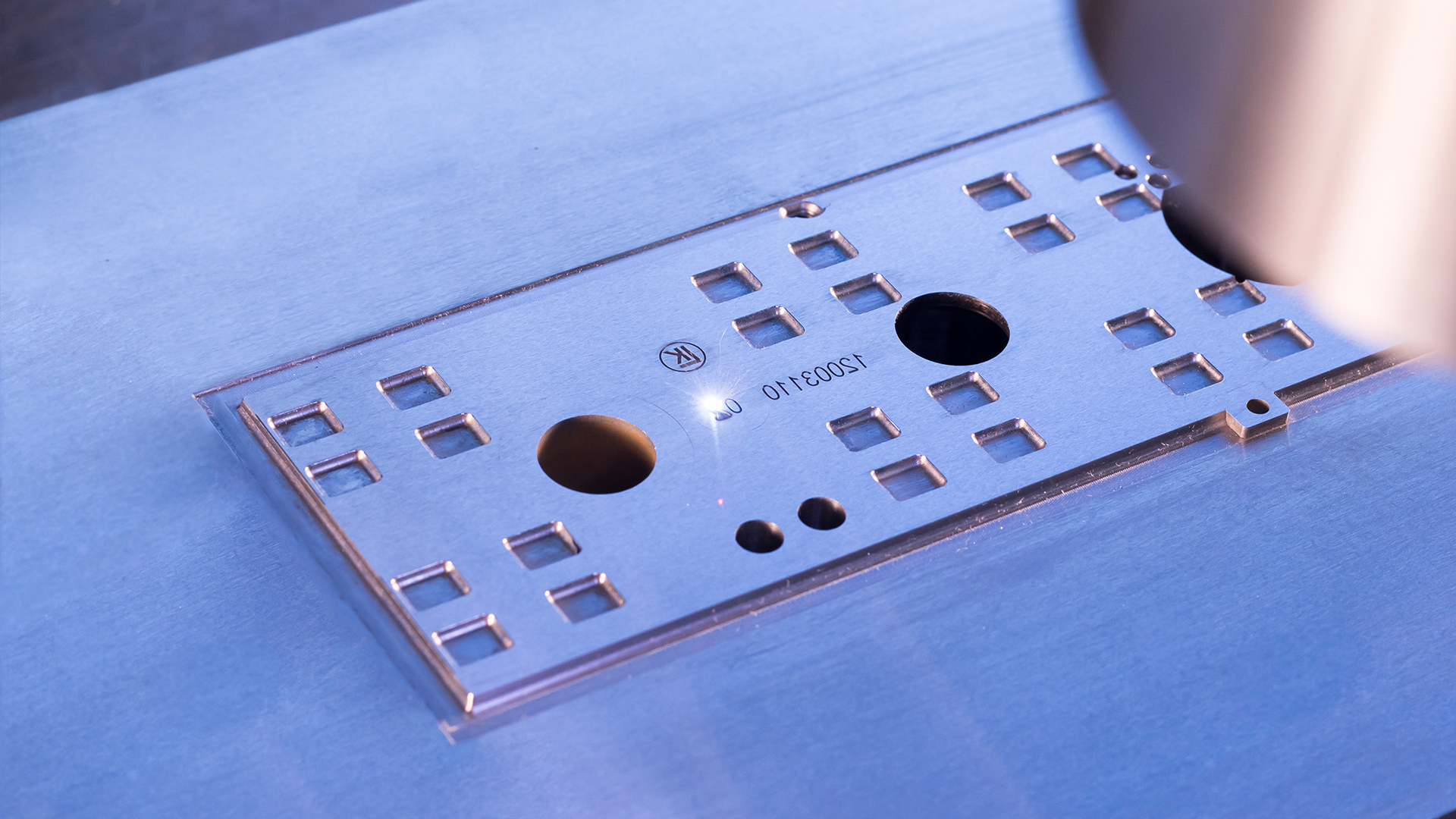

Typical applications of this highly versatile technology are plastic injection molds, copper electrodes, turned and milled parts or aluminum dies. We are also experienced with special engravings for aerospace technology.

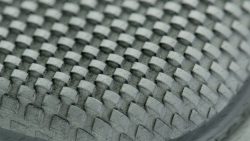

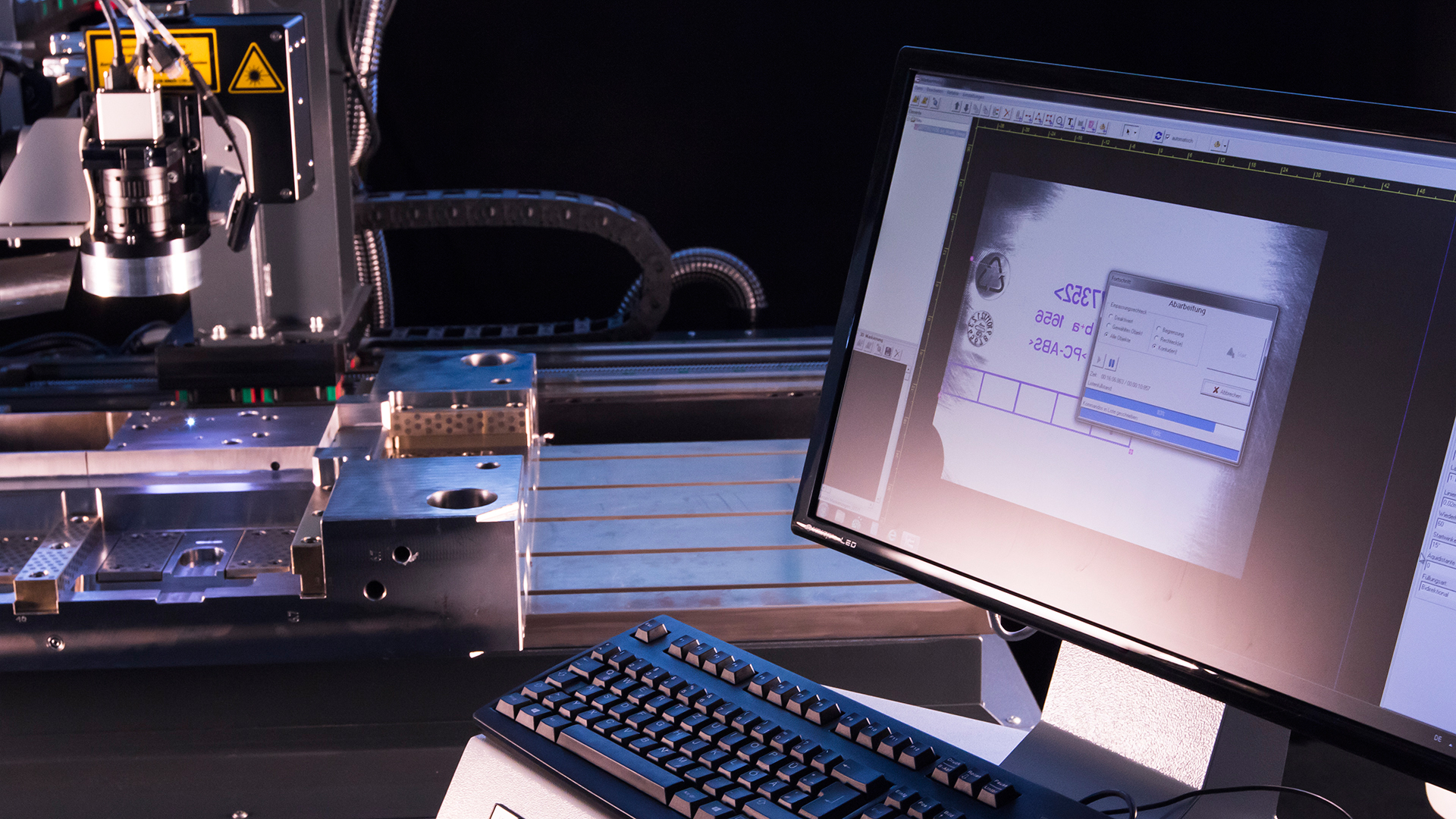

3D Laser Engraving

In the case of 3D laser engraving, the surface of the workpiece is removed in a defined manner, with the material being evaporated layer by layer, so the desired contour appears in the end.

This method enables predefined flank angles of die stamps to be realized, as well as complex three-dimensional structures, which are used on dies for striking coins or tools for mold construction.

The appearance exceeds the results of a milling procedure, as the milling tool itself always leaves a certain radius on the surface, whereas the laser beam creates the desired shape accurately with sharp edges.

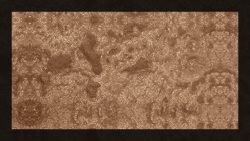

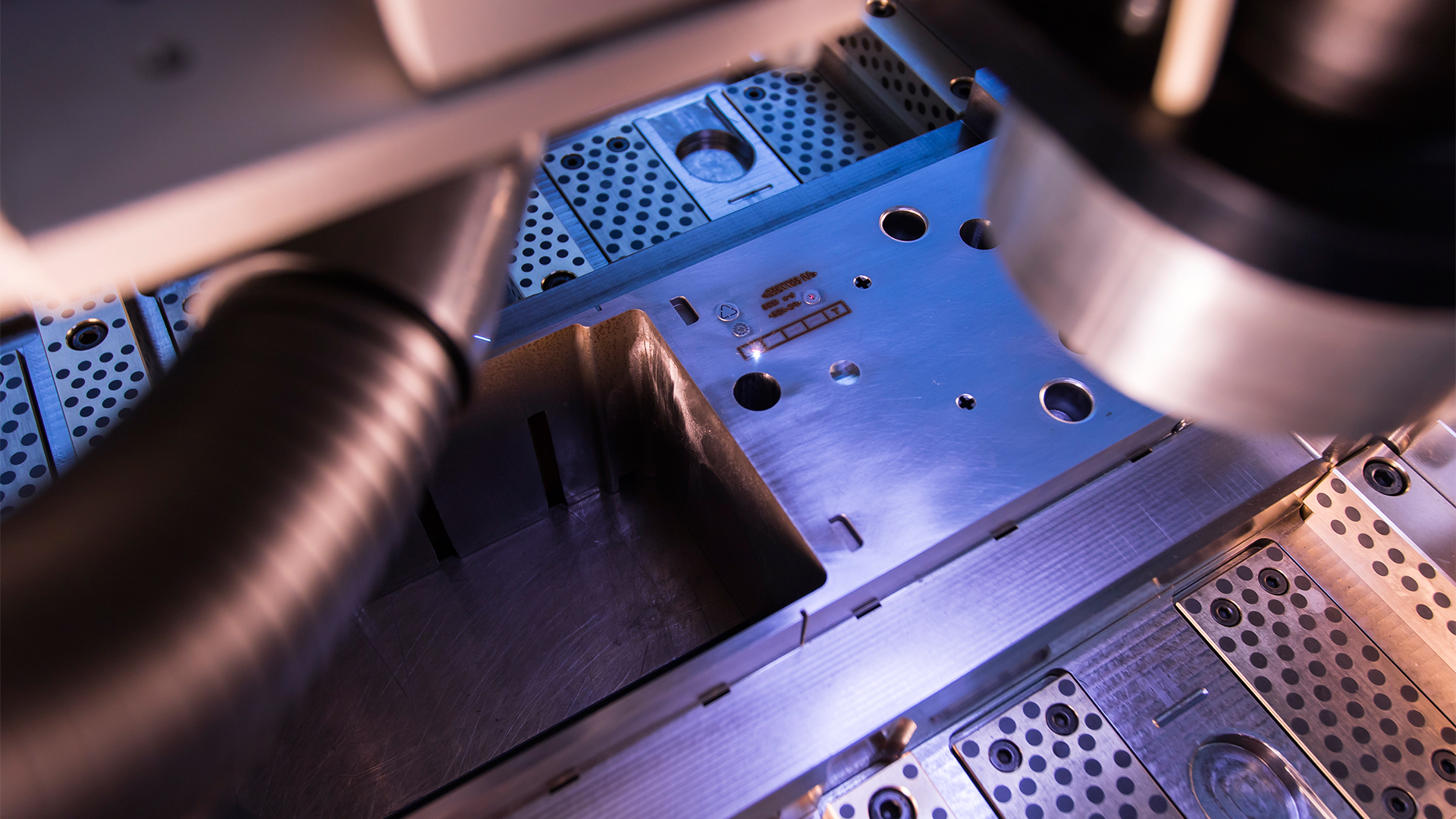

Surface Structuring and

Mold Texturing according to VDI 3400

Our laser can be used for defined structuring of surfaces, e.g. textures may precisely be applied to particular zones in injection molds or mold inserts.

These structures may be composed of geometrical elements, e.g. to create an optical impression or of irregular structure elements, which are common applications for embossing of leather or production of a brushed wood structure.

Patterns used for these purposes may be saved and recalled anytime, ensuring a reproducibility of 100%. This feature is not possible by chemical etching.

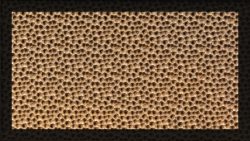

Micro - Engraving

By means of highly precise engravings in the mm range, a nearly forgery-proof authenticity certification becomes possible.

As the results are not restricted to point- or line-shaped objects, complete shapes may be generated by removing layer by layer. This fact represents an enormous progress for authenticity certification in the range of µm.

Typical applications include die stamps for authenticity certification, seals of quality or creation of forgery-proof protection markings.