Laser Cutting

No limits to desired contours.

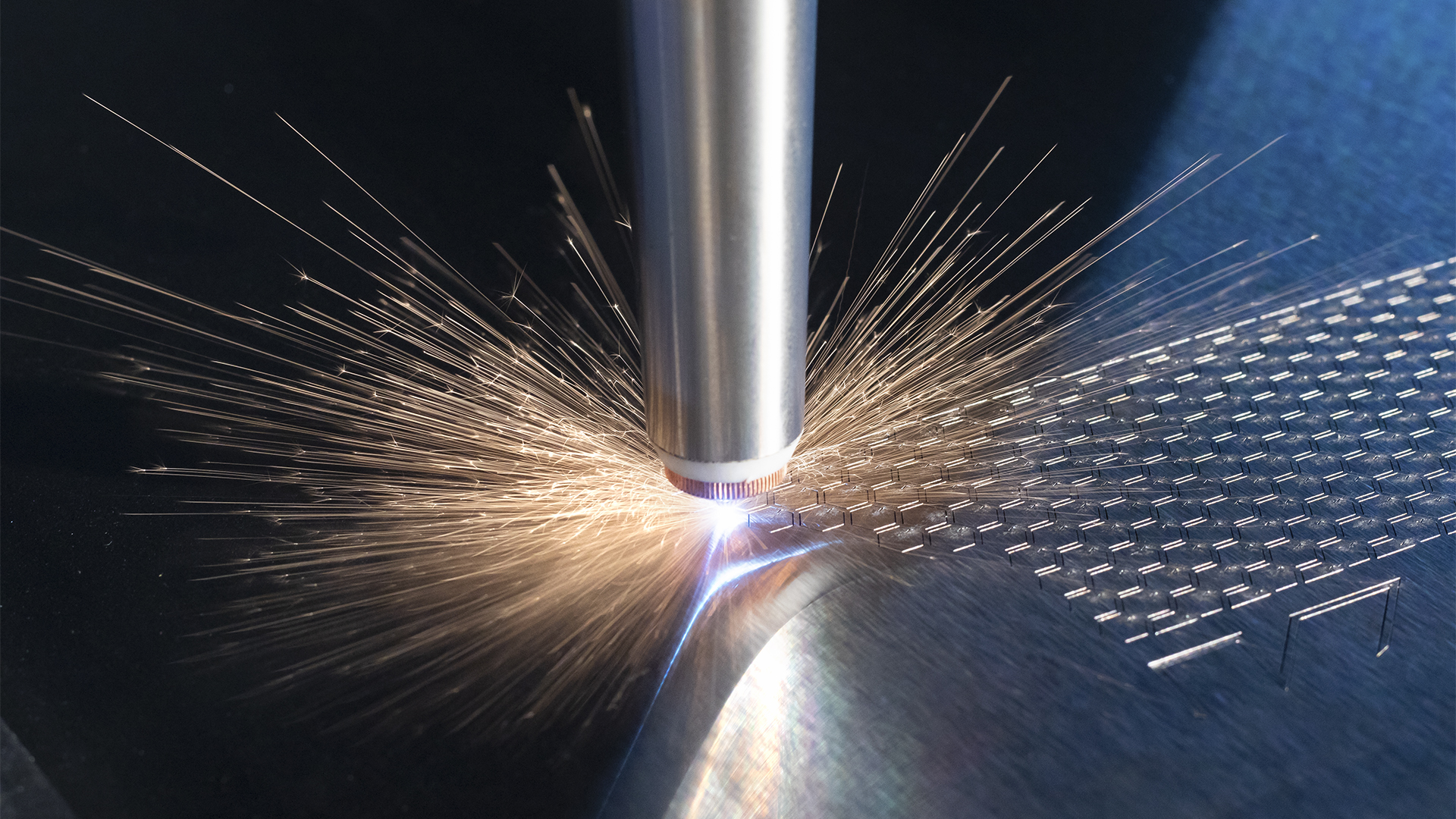

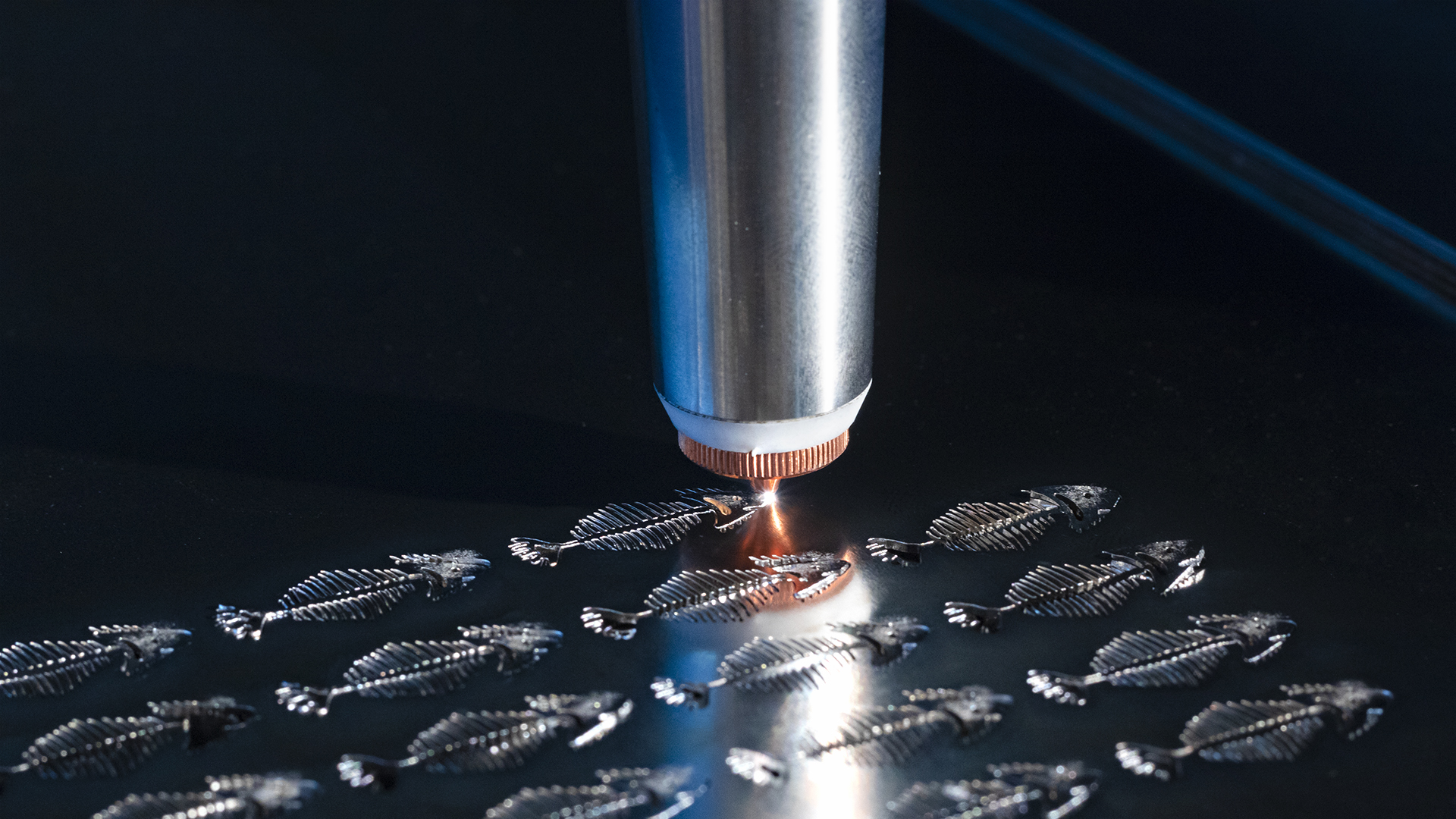

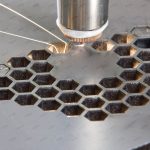

As no contact acts on the material surface in the course a laser cutting procedure, laser boards can be produced without or nearly without burrs. Cutting edges are clean – no rework is required. Thanks to the low heat input, boards remain plane, and warping can be neglected.

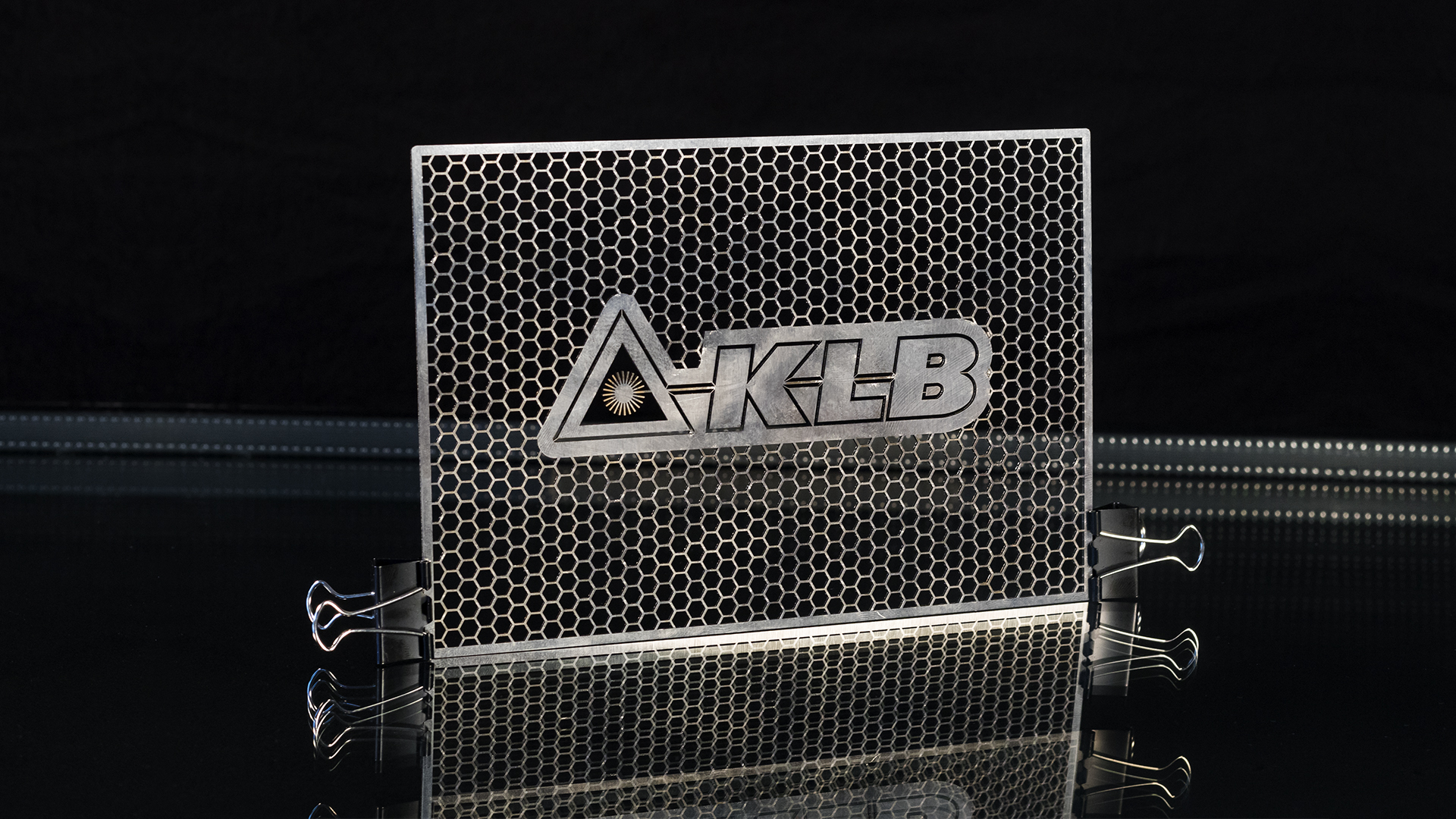

In their daily work, our specialists are accustomed to cutting various kinds of materials in different thickness, e.g. tool bases consisting of spring steel (1.4310), copper boards and plugs for the automotive sector -among others electric drives-, as well as small and large series of parts made of aluminum, steel, stainless steel as well as of various brass and copper materials. Special materials like Böhler K55 can be processed in outstanding quality as well.

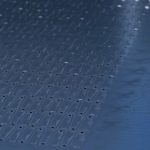

Our laser fine cutting center cuts wafer-thin foils up from 0.01 mm and metal sheets up to 5mm, at an accuracy of 20µ. For thicker sheets (up to 18mm), the precision amounts to 0.1mm.

Applications for boards processed by laser cutting can also be found in medical technology, precision and electrical engineering.

We are looking forwards to receiving your inquiry in .dxf format, and to cutting also your prototypes, samples and series…

Benefits

- Useful for a great variety of materials in different thicknesses

- Clean edges without burrs, no rework necessary

- Narrow kerfs (0.1 mm) and precise contours

- Excellent accuracy by laser fine cutting, even 20µ possible

- Deformation considerably reduced, thanks to low thermal input

- Board dimensions can be adapted anytime by CAD/CAM system

- As no mechanical cutting tool is used, interruptions caused by corresponding maintenance do not exist

High Flexibility

Programming takes place in CAD/CAM systems, so cutting shapes can easily be modified.

Laser cutting is of interest for:

- Tool and mold making

- Automotive sector

- Electrical engineering

- Medical technology

- Forging technology

- Precision engineering

- Filter technology

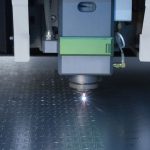

Laser Fine Cutting

Precision cutting in the µm range.

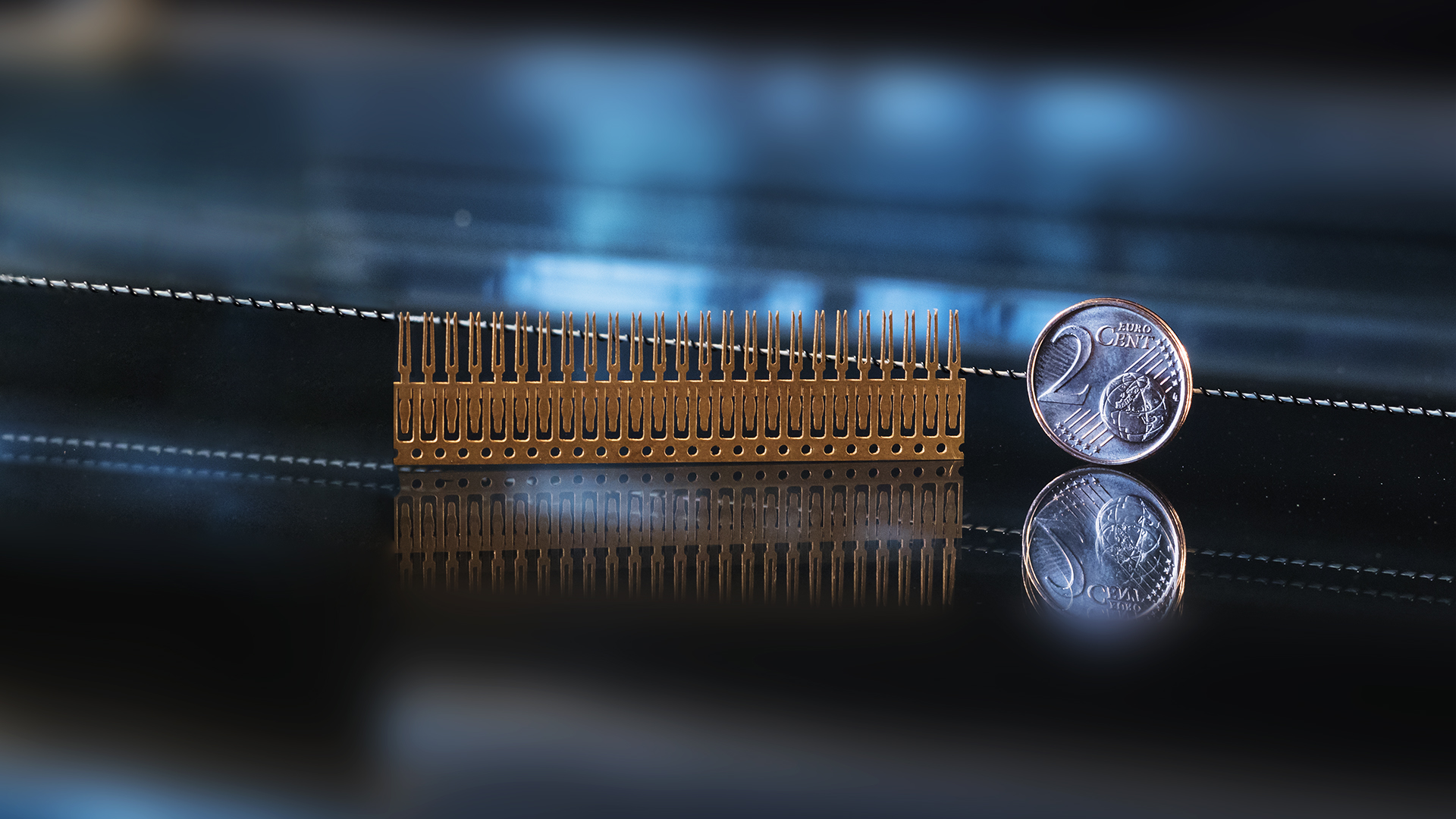

For thin sheet metals, the process speed of laser fine cutting is comparable to punches – completely without tool cost.

Our laser fine cutting center cuts wafer-thin foils up from 0.01 mm and metal sheets up to 5mm, at an accuracy tolerance of 20µ. On the basis of the linear drive provided, the dimensional accuracy can also be maintained for large-scale production.

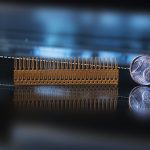

As very narrow kerfs of 0.1 mm are possible, we are able to cut filigree and even finest boars and plugs. For your orders above 5mm sheet thickness, the precision tolerance still reaches 0.1mm.

Clients from tool and mold making often order entire sheet sets, i.e. a board shape originating from .dxf data set is manufactured in different material thicknesses (for instance packages comprising elements of 0.2/0.4/0.5/0.6/0.8/1.0/1.5/2.0/3.0mm thickness). Tool bases are often required to reestablish the original height dimension of a tool, as its height may be reduced due to resetting or abrasion of the surface. Boards we cut, made of spring steel (1.4310), are extremely resistant to pressure and appropriate for this purpose.

We are looking forwards

to receiving your inquiry in .dxf file format …

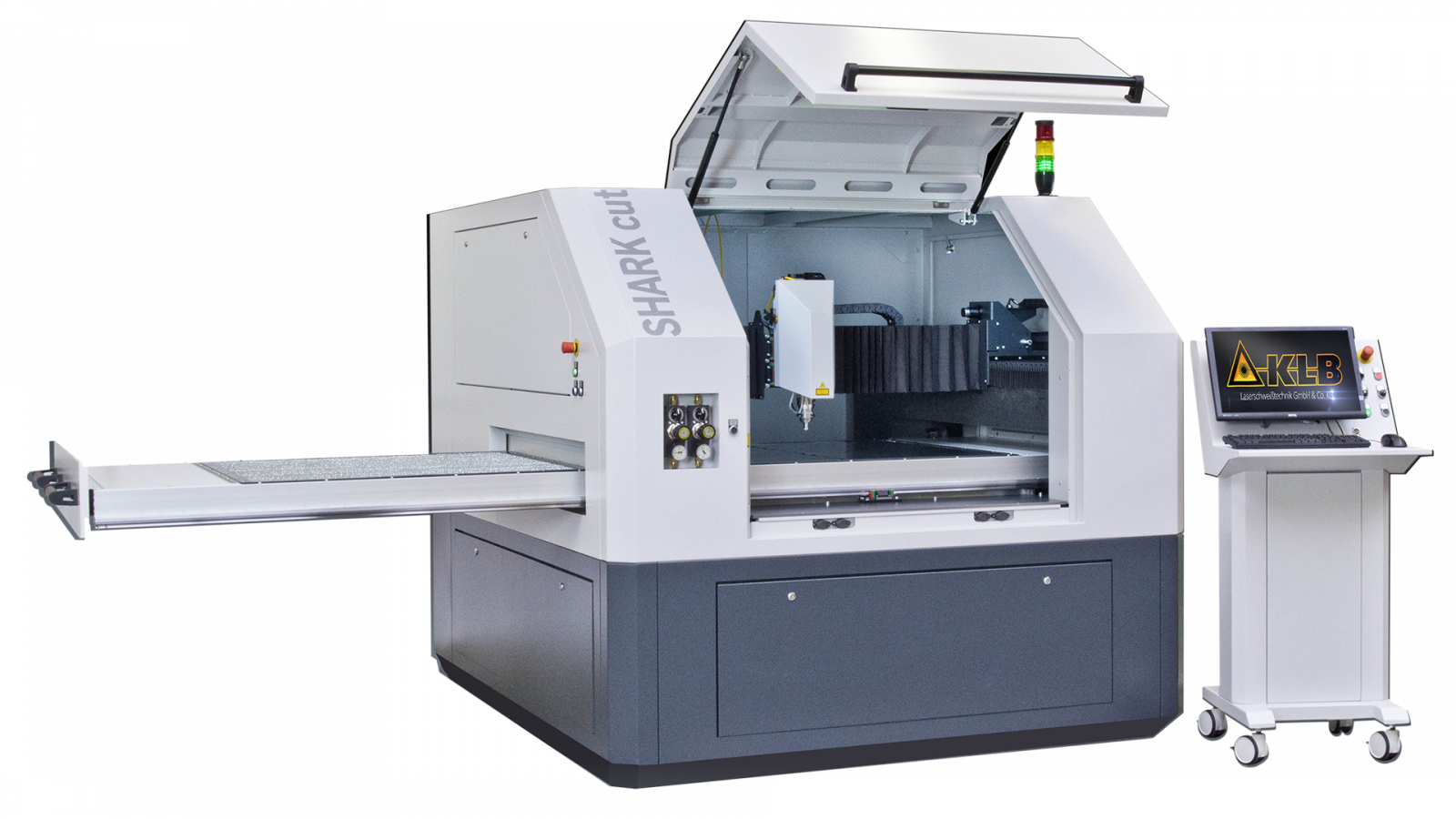

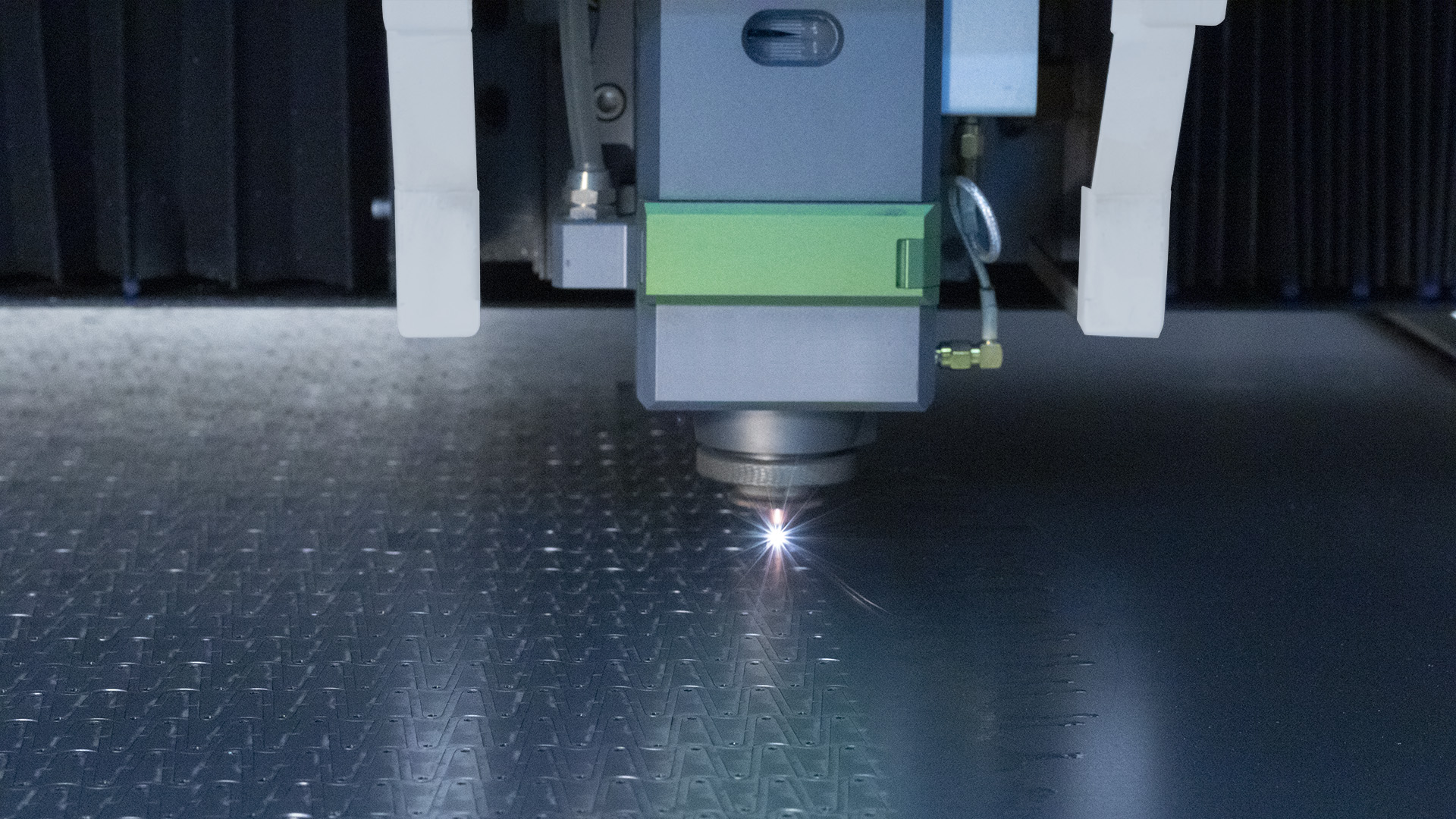

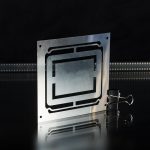

Our SHARK-Cut Machine

High-Speed at maximum precision » an uninterrupted process.

For thin sheet metals, the process speed of laser fine cutting is comparable to punches – completely without tool cost.

Our methods are continuously upgraded. For this reason, we make use always of technology which is up-to-date. Our new SHARK-Cut machine with quick-exchange drawer is always ready to process your orders in an uninterrupted sequence. Still in the course of the process, the previously cut boards are removed from the other side of the drawer and new items inserted – and the process does not stop running.

This feature proves to be extremely practical for large-volume production: The process speed rises by factor 2, without affecting the accuracy of 20µ.

Laser fine cutting at an incredible speed!

You don’t believe?

Come and see yourself.