Rental Service for Machines

Renting instead of Buying...

Processing of components by laser and welding technology is our main business. Should you prefer however to perform yourself treatment of components at your site without purchasing an own system, our assistance will be of major benefit, too:

Additional capacities sometimes become imperative, due to an increase in production, an emergency case due to machine failure or an unexpected order volume. For these situations, we offer you the alternative of renting or purchasing a machine, configured according to your requirements. Our flexible and exclusive machine service will miss no chance preventing a production stop at your site. . .

For renting, a large choice of mobile machines is at your disposal. Contracts on a daily, weekly or monthly basis are possible. We rent out the desired model in a flexible way anytime, an optimum service for projects requiring just-in-time delivery.

Our customers can count on our active collaboration and our engagement. The best method for transaction can be discussed in an unbureaucratic manner.

Our mobile machine park offers enormous flexibility to our clients: From robotic systems for laser hardening and laser powder deposition welding, laser welding systems, laser welding units with handgun up to laser cleaning models as well as TIG and MIG/MAG equipment.

It’s your own choice ...

Which machine type is in question?

- Mobile robotic unit for laser hardening (3KW / 6KW)

- Mobile robotic unit for laser powder deposition welding

- Mobile laser welding system with crawler chassis (300W / 900W)

- Mobile laser welding unit with handgun (2KW)

- Mobile laser cleaning system (50W / 100W / 1500W / 2000W)

- Fronius welding equipment TIG- or MIG/MAG

- Chamber and hardening furnaces (50L / 100L / 300L)

Renting our up-to-date machines is always a clever alternative for flexible order processing at a favorable price. This ensures a reliable production run meeting your deadlines.

Do not hesitate and contact our service team. We will find an optimum solution for a rental machine.

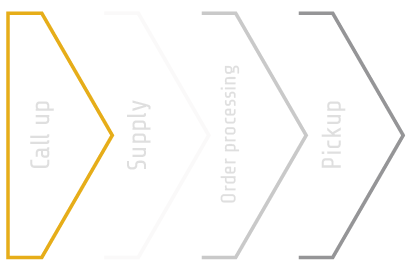

That’s the way to proceed . . .

Present the project

to our staff:

+49 (0)2722 / 63 59 140

Anytime, any procedure:

Machine type, rental period, place and time of handover delivery can be agreed with our service team according to your needs.

Exclusive transport service:

We organize the delivery of the machine and pickup at the end of the rental period.

We offer solutions for any requirement.

Delivery and Pickup service

Our exclusive delivery and pickup service is always at your disposal. It is enough to agree the relevant dates – the rest is our own responsibility.

Training

As we use all of the machine models which we sell also in our own production, we know every detail. For this reason, we are a competent partner for instruction of your personnel regarding operation and safe work. Training can be carried out on site.

Project assistance

Our service is not restricted to the delivery of the machine itself. Our specialists may also be charged with supervision of the process in question or further support for the project. Simply talk to us, we are ready for assistance anytime.

Emergency service around the clock

Machine failure? We are prepared and can be reached around the clock, also during weekends and holydays. Reaction is ensured without delay.

Our 24h Hotline:

+49 (0)171 624 38 30

+49 (0)151 418 697 83

Self-propelled. Self-scanning. Exchangeable head.

Large machine components or extremely heavy tools and molds – thanks to this mobile laser robot, hardening and laser powder deposition welding are considerably simplified, as the object in question can remain in place. Mounted on a crawler chassis, the robot moves around the component, always stopping at the position required. We use this system for mobile applications at the site of the client. An adequate tun-tilt positioner can be ordered as well, sometimes required for particular projects for flexible 3D treatment. The laser heads for hardening and powder deposition welding (with supplementary modules) are exchangeable. The AL ROCK machine is equipped with a scan system to register the shapes to be processed, for subsequent data processing and efficient welding or hardening of the desired surfaces according to the requirements.

Laser hardening by AL-ROCK

In free 3D motion, the laser beam precisely traces the shape of the workpiece. This way, hardening of closing edges, grain structures, nubs or single points is really not a big deal. The temperature dependent control of laser power supplies the heat exactly to the spot desired, without applying any excessive thermal load on adjacent zones. For quality control, the process is meanwhile documented, so process safety and reproducibility are ensured.

Laser-powder deposition welding by AL-ROCK

In the course of a laser powder deposition welding procedure, the laser beam first slightly melts the component surface, then a gas stream injects filler metal in the form of powder into the bath. This process generates a metallurgically bonded layer with least possible dilution with the base material (less than 5%), free of pores and cracks. This method is useful for repair or coating of components, to enhance surface properties or upgrade geometrical parameters. Even large damages can be repaired quickly and nearly without trace. The tool afterwards can immediately be reused without any restriction. Design changes are possible as well.

Use laser powder deposition welding for modification of components by wear protection coatings, or repair of damaged or worn items.

Options for AL-ROCK:

- Mobile laser guards

- Turn-tilt positioner

- Mirror system and beam splitter

- Weld fume extraction

- Mobile working table

- Mabotic Scan system

Benefits AL-Rock:

- Mobile system: Self-propelled crawler chassis.

- All-over temperature supervision by IR: Highest process safety also at cutting edges – heat supply can precisely be controlled.

- Turn-tilt-table: Maximum flexibility in 3D treatment by robot-guided laser.

- Double mirror system: Shapes difficult to access can be hardened in a targeted procedure.

- Mabotic-Scan system: The area to be processed can be captured by scanner before initiating the treatment.

- Documentation: The entire temperature and power variation can be appended as PDF log.

Benefits of laser hardening:

- Thanks to low warping, rework cost can be neglected or is even absent

- Process chain is shortened, as hardening can be carried out after completion of treatment

- Lowest risk concerning cracking

- Zones subjected to wear can be localized and hardened precisely following the contour

- Penetration depth depends on material and amounts to 1.5 mm max., in contrast to nitration

- Highly flexible, process fits just-in-time delivery

Possible of applications of laser hardening:

- Bend radii and particular areas of molds

- Forming and cutting tools

- Closing edges of dies

- Impellers and gears

- Spindle, shaft and worm drives

- Guiding devices and stop faces

Benefits of laser powder deposition welding:

- Outstanding process speed

- High economic efficiency for large areas

- Low mixture with base material (less than 5%)

- Reduced warping thanks to low thermal input

- Excellent accuracy and reproducibility (serial production)

- Large possibilities for base and filler materials to be combined

- Homogenous surface structure, not difficult to machine

Typical applications for laser powder deposition welding:

- Turbine blades

- Pistons

- Valves

- Shafts

- Tools of any kind

CW- or Pulse- Mode. Consistent welding process without repositioning. Self-propelled. Programmable.

Welding positions in complex shapes or in recesses may be extremely difficult to reach. For the ALFlak machine however, this is no problem, as it features a laser arm with large projection. For this reason, the welding process can be carried out in a single sequence without interruptions due to repositioning. Welded seams of up to 500 mm are possible in a single run. For the fiber lasers, power versions of 300W and 1200W are available. The resonators have been milled from solid metal to provide for optimum beam quality. Besides movable objectives, a sophisticated pivotable beam deflection is integrated, so welders can perform their work from a comfortable ergonomic position, with trouble-free access to each welding position anytime.

The rugged high-performance laser systems, originating from ALPHA LASER, are perfectly prepared to carry out complicate joints, nearly impossible to handle by conventional methods – also in direct vicinity of sensitive objects made of plastic and glass. As laser energy and reaction time are precisely controllable, even metals with high melting point and thermal conductivity can be welded in pulse or CW mode. Different metals can mutually be connected as well. Whether for repair, modification or for production of entire series, top quality treatment of sheet metal, aluminum, stainless steel and section steel is out of question.

A comprehensive range of accessories is available to meet also most specific requirements:

- Turn-tilt-objective (for ALFlak 900 F with water cooling)

- AL Flak 900 F also to be equipped with option powder welding deposition welding

- Powder nozzle and powder conveyor (for ALFlak 900 F)

- Rotary axis module with chuck, tiltable, selectable rotary motion between horizontal and vertical

- TV-System for monitoring and visual control of welding process

- Ergo-wedge allows comfortable working position

- LAfet® – programmable laser wire feed system

- Water cooling for optical components and sealing air as an option (CrossJet)

Benefits:

- Even difficult welding position are within reach, thanks to laser arm with large overhang

- Continuous welding sequence without repositioning

- Pulse or CW mode

- Pivotable beam deflection and special wedge ensure comfortable working position

- Touch-Display. Set-up of laser parameters additionally by multifunctional foot switch.

- Lowest energy transfer to workpiece surface

- Neither spatters nor incursions

- Precise and targeted energy input for extreme reduction of warping

- Also on finest shapes, material can be applied without difficulty

- Minimized rework cost

- Microstructural changes nearly absent

- Delicate treatment at precisely defined positions

- Suitable also in zones of difficult access

Applications:

- Welding of precision metal components

- Repair of extended and delicate defects in tools and molds

- Design changes, from smallest molds up to extremely heavy tools

- Welding of surgical instruments

- Passive and active implants, endoscopic components

- Thermocouples, sensors and pressure diaphragms

- Electronic housings

- Stainless steel parts for appliances, architectural elements and sculptures

Mobile Laser Hand Welding Units

Increased speed, maximum user friendliness and a wide scope of applications belong to the major benefits of laser hand welding method, which is currently revolutionizing the industrial market. Compared to well-known TIG welding, it exceeds the speed by factor 4. Users become quickly familiar with the method and are able to deliver good results within short time. Positioning of the laser gun does not give rise to difficulties, even in locations to reach. This extends the scope to highly complex assemblies.

Besides practical points of view, the excellent quality of the resulting seam proves to be an advantage of this method. Warping is considerably reduced -compared to seams produced by TIG welding-, and the optical appearance of fillet welds is enhanced without any negative impact on mechanical properties.

Lower warping thanks to targeted heat input -

Maximum productivity and flexibility.

Only one quarter of the working time usual in a TIG – welding procedure is needed for comparable laser welding. Simply position the lightweight laser gun (0.5 kg) at the required place, no matter if it is difficult to reach. Welding nozzles are selected according to the requirement: Fillet or butt welds, corner welds or outside seams. The concentrated energy input enables homogenous root seams to be produced.

Costs for preparation and rework, e.g. for grinding and polishing, are often no more necessary – this represents an economical advantage over conventional methods. Furthermore, as the method manages without large heat input, reduced warping contributes to elimination of straightening work normally required.

For various materials and a wide thickness range, laser welding delivers valuable and reproducible results with excellent mechanical properties. Personnel can conveniently be trained without major effort. Even welders with many years of experience are surprised by the results.

Our factory service is looking forward to presenting you the equipment in a live demonstration anytime.

Innovative Highlight:

The Double Wobble Welding Head

This specially developed wobble head increases the welding width additionally up to 5 mm, thus spanning also larger gap dimensions without any problem. Frequency and width of wobble welding can be set according to the application in question. This results in an increased variety of processing possibilities, as stable and visually appealing welding seams can be produced even in the case of difficult gap dimensions.

Technische Daten:

| Laser power Laser wave length Penetration depth Laser source type Humidity Admissible ambient temperature Power supply Cooling method Power consumption Length of fiber optic cable Laser spot diameter Laser head Safety button Alarm lamp Weight and gun Machine dimensions (WxHxD) Gross weight machine |

2000W 1064nm <5 mm (depending on laser power and material) Fiber laser <70% <40°C (32A) Water cooling 8800W 10m, up to 15m as an option 0-5mm Patented Mini-Wobble head yes yes 0.5KG 632 x 1240 x 1204mm 238KG (incl. cooling water) |

Application in different sectors:

- Tank construction and equipment engineering.

- Mechanical engineering.

- Plant engineering.

- Metal and sheet metal processing.

- Pipe production and processing.

Benefits:

- Process speed exceeds TIG welding by factor 4.

- Simple to learn and to practice.

- Narrow and durable welding seams, good optical appearance.

- Homogenous root seams are possible.

- Suitable also in positions difficult to access.

- Low heat input into material surface.

- For this reason: Considerable reduced warping

- Neither spatters nor undercut.

- Treatment possible in precisely defined places.

- Appropriate for both thick plates and thin metal sheets.

- Low rework cost.

- Minimum maintenance.

- Low operating cost.

Features:

- Models with single or double wobble welding head available.

- Flexible adjustment of laser spot diameter between 0 and 5mm.

- Precision software for wire feed under automatic control.

- Double wobble welding head with 6 welding patterns.

- Simple use: Welding parameters pre-configured, focal length simple to adjust.

- Lifetime of rotating deflection mirrors increased by factor 6.

- Fiber laser with water cooling for permanent use.

- Lightweight handgun for welding: Only 0.5KG.

- Length of flexible fiber optic cable: 10 m, up to 15 m as an option.

- Lifetime of the machine: 10 years min.

- High efficiency, low space requirement, high flexibility.

- No UV radiation and ozone formation by laser welding.

- Outstanding price / performance ratio.

- Menu language selectable.

- Warranty: 2 years for laser source, 1 year for other components.

Non-contact cleaning. Quick, intense and still gentle to material.

Without any effort, rust, lacquer, oil, soot coatings, oxides and many other contaminations can be removed from metal, wood, natural stone and concrete. Our mobile laser cleaning systems clean every surface in a non-contact procedure without leaving residues.

The base material itself is not damaged, and -thanks to fine-tuning of parameters- even the state of high gloss polished surfaces remains unaffected. The laser beam cleans the surface without leaving a trace. Rust and oxide resistance of stainless steel and aluminum remain intact.

Pulse power, scanning rate and cleaning pattern can be fine-tuned, so that the material quantity removed by a single laser pulse can be controlled at maximum precision.

The absence of chemical solvents or other consumables contributes to high environmental friendliness as well.

The laser can be operated by hand gun, so that all positions of difficult access can be reached. Fine-tuning of laser parameters is done in no time, by means of the tablet included in the delivery.

The correct cleaning power for every application:

The laser cleaner 100 W proves to be the right choice for sensitive surfaces and delicate tool molds. This compact and portable model can be carried around and used inside cases, containers and pipes.

Cleaning of large areas and intensely contaminated components are the specialty of the 1500W laser cleaner. The enormous power eliminates dirt even from oily and rusty threads and textures in a flash.

Possible applications:

- High-End cleaning of plastic injection molds

- High-End cleaning of tool molds

- High-End cleaning of surfaces

- Cleaning of weld seams

- High-End cleaning of motors and accessories

- Cleaning of surfaces consisting of concrete or natural stone

Benefits:

- Simple to learn and to practice.

- Dry and clean

- Low noise level

- In contrast to blast clean, no edge rounding produced

- Base material is neither removed nor damaged

- Surface remains free of scratches, thanks to non-contact technology

- Also for polished and very sensitive surfaces

- Surface structure and high gloss properties remain unchanged

- For small and large areas

- Zones hard to reach do not represent an obstacle

- Thoroughness and efficiency exceed the results of many other cleaning methods

- Accurate and controllable beam

- Residues nearly absent

- Quick procedure and minimum delay

- Integration in production and assembly lines possible

- Minimum maintenance

Mobile FRONIUS equipment for TIG-welding: magicWave2200 featuring up to 220 Ampere welding power.

Mobile FRONIUS Schweißgeräte zum MIG/MAG- Schweißen:

Die TPS600i bis 600 Ampere Schweißleistung

Thanks to its high welding power, model TPS 600i is perfectly suited for applications in the sectors of heavy steel construction and machine building, as well as for all tasks to be performed by single wire process with extremely high rate of deposition. The welding power source can deliver a welding current of up to A at a welding voltage of 44 V und 60 % duty cycle. The temperature absorption can be reduced by up to 80%, due to the integrated water-cooled gas nozzle and new geometry of the contact tube. Even after a longer welding sequence, the torch cools down again to room temperature within short delay. Cleaning is simplified by a sophisticated wear part design; this contributes also to reduced expenses for wear parts. The cooling unit CU 1400i PRO MC has been designed for efficient heat dissipation caused by thermal load arising during high performance welding. An ECO mode is provided offering dynamic control of the cooling circuit with the purpose of saving energy. The pump speed is controlled depending on the temperature in the return line for cooling liquid.

Our new mobile induction plant „Powerduction 220LG“ for induction hardening, brazing, debonding, heating, annealing, solving and straightening of components – supplies continuous heating power of up to 22kW, is equipped with efficient liquid cooling and suitable for many metals including aluminum. The quick and precise heat transfer acts on the metal component and avoids damaging. Targeted flameless heating precisely on the spot is essential when working in the vicinity of cables, tubes and other objects sensitive to heat, so previous dismantling work can be omitted. The three-phase device has been designed for intense industrial applications. Heating power can be adjusted in steps of 10%.

Applications:

- Straightening of distorted frames and welding structures

- Loosening of bolts, ball joints without damage to the boot

- Dismantling of exhaust systems and flanges

- Annealing of metal parts

- Heating for bending procedures

- Debonding of steel and aluminum components

- Brazing

- Induction hardening