Laser Cleaning

A quick and intense cleaning procedure –

and still gentle to the material.

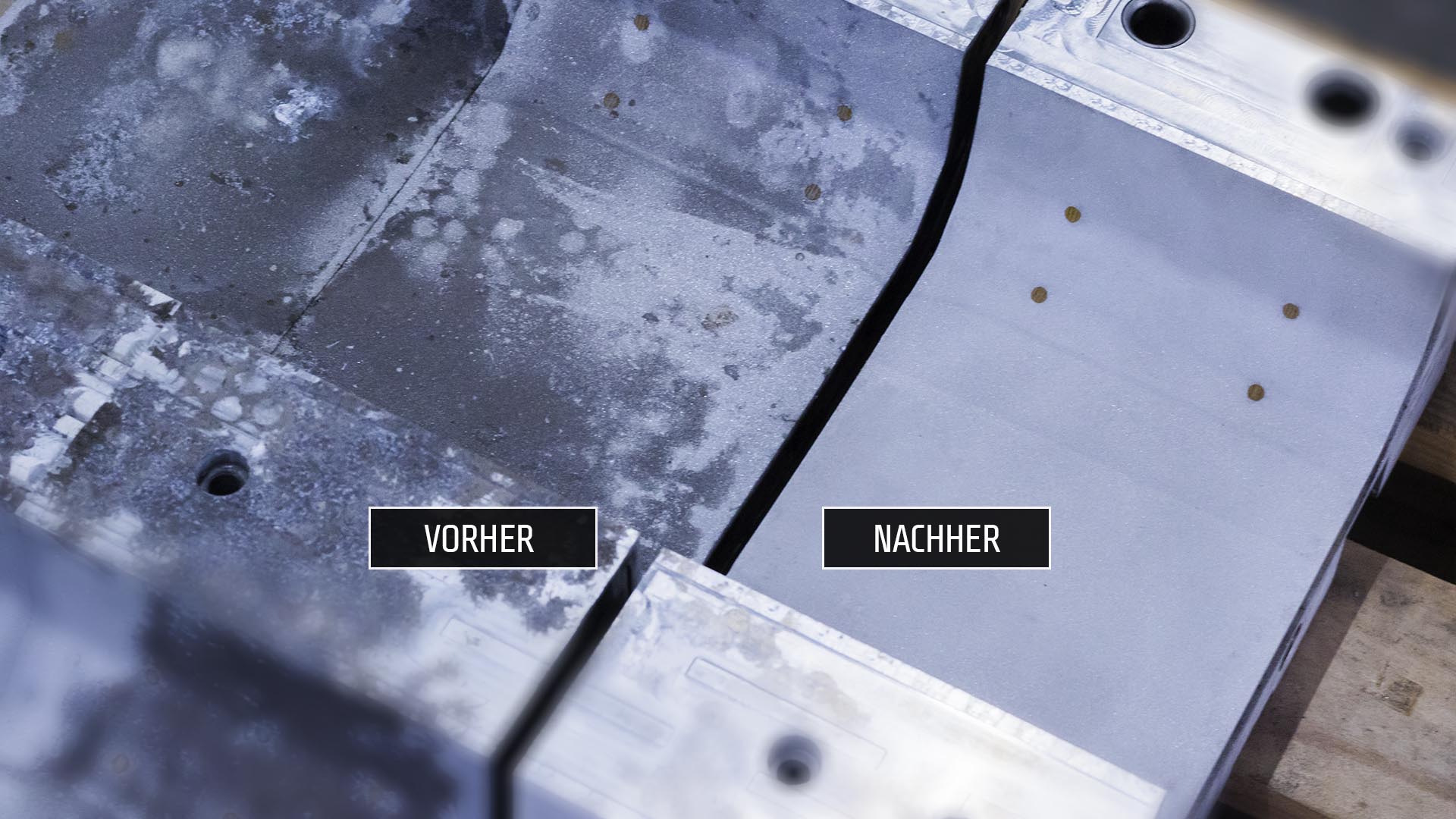

This new and innovative laser technology revolutionizes not only the industrial sector, but conquers also more and more private fields of application. Removal of varnish, decoating, derusting and removal of contamination belongs to the tasks comfortably to be carried out by this method. Surfaces are cleaned thoroughly and intensely, and parts after treatment prove to be completely regenerated, even for very comprehensive measures. By means of the concentrated energy of the laser beam, we eliminate for you without any problem deposits from injection molds, rust, lacquer, oil, soot coatings, oxides and many other contaminations from metal, wood, natural stone and concrete.

Thanks to the recently developed method, cleaning of the surface takes place without damage to base material and edge rounding. The laser features a specific wavelength acting only on contamination of any kind and not on the material of the part being cleaned. The non-contact procedure, based on precisely targeted energy input, is also convenient for zone difficult to access.

Discover yourself a new level of refurbishment…

Originally developed for removal of rust, the models are used for restoration of natural stone façades and many other purposes: Removing paint, decoating, cleaning of tool molds, degreasing, special surface treatment and even removal of graffiti. Applications range from tiny areas up to large surfaces in public or private infrastructure.

Benefits

- Dry and clean

- Low noise level

- In contrast to blast clean, no edge rounding produced

- Base material is neither removed nor damaged

- Surface remains free of scratches, thanks to non-contact technology

- Also for polished and very sensitive surfaces

- For small and large areas

- Zones hard to reach do not represent an obstacle

- Thoroughness and efficiency exceed the results of many other cleaning methods

- Accurate and controllable beam

- Residues nearly absent

- Quick procedure

- Minimum delay

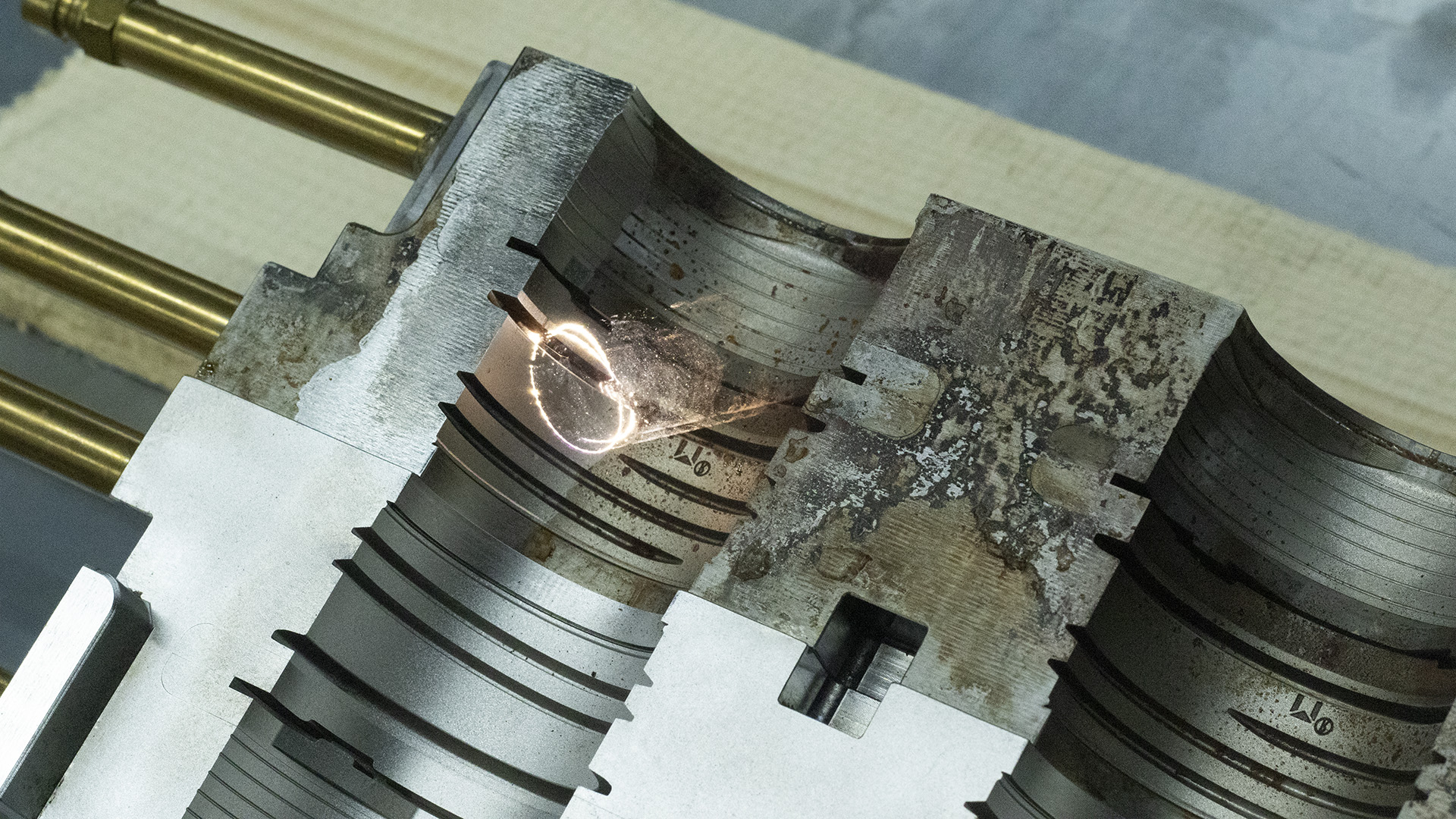

The concentrated energy transfer to the surface and the sudden temperature increase creates an effect similar to an explosion, causing impurities to vaporize at once without leaving a trace or residues.

The absence of chemical solvents or other consumables contributes to high environmental friendliness, too.

Technology of Laser Cleaning

Laser cleaning -or ablation- represents a method to separate undesirable material from a fix surface in a non-contact procedure. The adherent particles absorb the energy supplied and vaporize at once without leaving residues.

In contrast to the impurities, the base material is insensitive to this energy and for this reason remains undamaged. Pulse power, scanning rate and cleaning pattern can be fine-tuned, so that the material quantity removed by a single laser pulse can be controlled at maximum precision.

Whether classical derusting of metal surfaces, removal of cathodic dip painting, cleaning of tool and plastic injection molds, restoring of motor or vintage car parts or wind turbines – for each component in question, we find appropriate parameters to create a laser beam with depth effect.

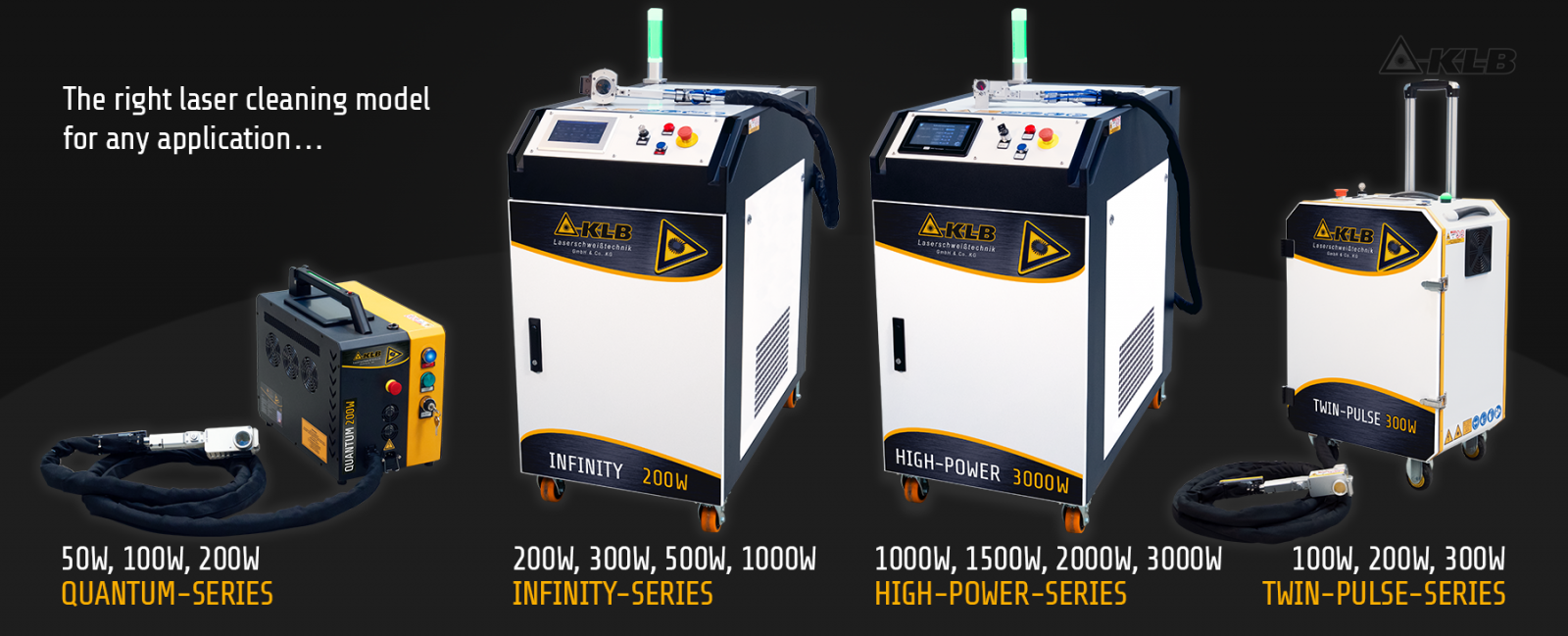

Your own laser cleaning system...

...exactly adapted to your particular needs.

Should you be interested in an own laser cleaning system, do not hesitate and consult our factory service. Customized solutions can be configured anytime. We inform you also about prices and delivery times. In between, we will be pleased to offer you a rental machine, so your project can be launched at once.

Purchasing one of our cutting-edge laser cleaning systems provides a stable basis for long-term order processing on site at lowest cost. We deliver only machines which we have thoroughly tested and used in our own production, knowing each model in detail. For this reason, we can offer service and support for the entire life cycle.

Choose the machine best fitting your applications. In order to assist your decision process, we invite you to a demonstration date anytime.

High-End cleaning of plastic injection molds.

The clever alternative to dry ice blasting.

Serial production of plastics which tend to adhere -like thermoplastic elastomers (TPE)-, over time often form deposits on the injection mold, which affect the surface quality of the injection-molded items. This phenomenon is encountered particularly in the case of polycarbonates doped with blends (PC+PBT). Negative effects of deposits increase with frequency of use of the mold, having an influence to the quality of the grain and thus impairing the optical appearance. If conventional methods (e.g. dry ice blasting) cannot solve the problem, the only remedy consists in costly reestablishment of the shape or production of a new mold.

In contrast to these methods, the concentrated energy of our lasers is able to clean and to regenerate the injection molds of our clients at a convenient price, removing deposits from the surface without leaving residues or affecting the base material. Blue and yellow discoloration of the injection mold disappears as well.

Wherever dry ice blasting fails, our laser machines ensure a clean surface!

High-End cleaning of tool molds

A cleaning process not entailing edge rounding!

Laser cleaning is the method of choice for our clients dealing with molds in the sector of metal sheet and plastics processing or glass machining. The base material is not damaged, and -thanks to fine-tuning of parameters- even the state of high gloss polished surfaces remains unaffected. The laser beam cleans the surface without leaving a trace.

High-End laser technology is a valuable assistance for careful removal of material deposits from plastic injection molds and aluminum dies. Fine eroded structures become clean again and look like new. A slight edge rounding, frequently caused by sand blast clean, is absent. Even adhering cold bending on warm forming cheeks can be removed by a laser beam in a gentle way.

´The perfect technology to make appear your tools LIKE NEW!

High-End cleaning of surfaces

Kein Schmutz bleibt für die Ewigkeit!No dirt can resist forever!

In order to make full use of the laser cleaning method for our clients, we have added some new steps to our service:

By means of rotary tables, even cylinders which are extremely heavy or -on the contrary- light as a feather, can be cleaned without effort, just by rotating them.

No logistics available? In the case of a lack of capacities, we are looking forward to offering you our transport service.

For fixed installations or objects which are very heavy, high or anchored to the floor, our mobile laser service won’t leave you alone.

We are also specialized in cleaning of ONSHORE- and OFFSHORE- wind power stations by laser technology.

New ways, new possibilities and efficient savings – all these benefits are offered by laser cleaning.

Cleaning of weld seams

Weld it. Clean it. Ready.

Thanks to laser technology, cleaning of welded seams is no longer a matter of concern. The absence of chemical solvents or other consumables contributes to high environmental friendliness as well.

The method is applicable for brass, cast iron, aluminum, steel and stainless steel – and the base material is never damaged.

Rust resistance remains intact as well. Pollutions like smoke residues originating from welding procedures however are removed, whereas sensitive surfaces e.g. made of aluminum remain undamaged, and their structure unchanged.

Don’t waste time with less efficient methods! A precious surface finish does not need black magic – a powerful technology is enough!

High-End cleaning of

motors and accessories

This tuning adds value to your vehicle.

Zones of difficult access in motor and gear, hard to clean by other methods, can be subjected to targeted treatment likewise, e.g. valve seats, gaps, clearances and recesses. The only parameter to adapt is the width of the laser beam, and even after corresponding reduction, it is able to penetrate into the smallest corners.

The surface of the components is not damaged, as the particularly selected wavelength of the laser only interacts with contamination of every kind, which is eliminated in a careful and cost-efficient manner.

This relates to baked-on residues of oil, soot, petrol and Diesel, as well as to adherent remainders of sealing compound. Gray oxidized and stained motor blocks are optically enhanced and have a high-class appearance after treatment. In the classic car business for instance, this is a decisive argument.

Are you interested? Simply describe your project, so we can offer advisory support and estimate the cost of the treatment.

Cleaning of tiles

Thorough, quick and cost-efficient for any surface size – for commercial and private applications.

Non-contact cleaning is particularly useful for zones hard to reach by other methods. Neither tile surfaces nor intermediate gaps are affected. The particularly selected wavelength of the laser only interacts with contamination of every kind, which is eliminated in a careful and cost-efficient manner.

Are you interested? Simply describe your project and the exact area size, so we can calculate the cost of the treatment.