Mobile Laser Welding

A combination of the advantages of laser welding with quick reaction and short process times.

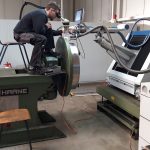

One call is enough and our staff is on site. Repair and surface modification of large machine components or heavy tools or molds are performed in no time. With a minimum of positioning work required, our mobile laser comes to your mold, or performs welding repair inside a machine.

For the clientele, this represents not less than considerable time and cost saving. Tools neither need to be removed nor reinstalled, no logistics and no new set-up of the machine are necessary.

The mobility offered is available at a favorable price. Our machine park comprises units disposing of 300W and 900W power, always prepared to ensure optimum flexibility to the clients and relieve them of set-up work. Our activities contribute to considerable cost saving and enhance their competitive position.

Benefits:

- Minimum of set-up time

- Time and cost saving

- No removal or reinstallation of components, no logistics

- No new-set up of the machine necessary

It’s just a question of efficient organization – we will be there within shortest delay.

Our mobile systems are equipped with different laser sources: 300 and 900 W. No matter if the challenge consists in treatment of delicate shapes or large areas. The appropriate laser type for the welding application is waiting for you. Even for large quantities of material to be applied, wires can precisely be welded in the range of mm. Application of thicker material layers reduces the number of process cycles – and saves time and money again.